A paintable lithium-ion battery has been developed at the lab of Pulickel Ajayan, a materials scientist at the Rice University. The study results have been published in Scientific Reports, an online and open access journal of Nature.

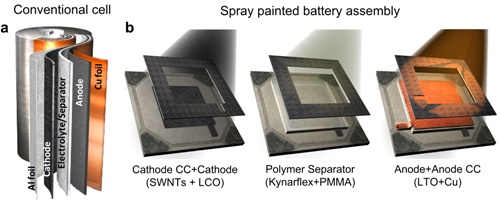

Conventional lithium-ion batteries wrap active layers into a canister or other portable container. But Rice University researchers have found a way to paint those layers onto any surface, which opens up the possibility of turning those surfaces into storage devices. (credit: Neelam Singh/Rice University)

Conventional lithium-ion batteries wrap active layers into a canister or other portable container. But Rice University researchers have found a way to paint those layers onto any surface, which opens up the possibility of turning those surfaces into storage devices. (credit: Neelam Singh/Rice University)

The rechargeable battery comprises five spray-painted layered components, which include two current collectors, an anode, a cathode and a polymer separator sandwiched between them. The researchers tested the adherence of the materials on different substrates by airbrushing them onto stainless steel, glass, flexible polymers, bathroom tiles and even on a beer stein.

During the test, the research connected nine bathroom tile-based batteries in parallel, of which one was mounted with a solar cell, which generates power from a white lab light. When the batteries were completely charged by the house current and solar panel, they were able to power an array of LEDs that illuminated the word ‘RICE’ for 6 h. Moreover, the batteries delivered a constant 2.4 V.

Rice researchers invent paintable battery

According to Neelam Singh, one of the researchers, the hand-painted batteries demonstrated a constant capacity, within ±10% of the set value. They underwent 60 charge-discharge cycles with a minimal drop in capacity.

The first layer is the positive current collector, a purified single-wall carbon nanotube mixture comprising carbon black particles in N-methylpyrrolidone; and the second is the cathode, which comprises ultrafine graphite (UFG) powder, carbon, and lithium cobalt oxide in a binder solution. The third layer is the polymer separator paint, which comprises a dispersion of silicon dioxide, PMMA, and Kynar Flex resin in a solvent mixture; and the fourth layer is the anode, which is a UFG and lithium titanium oxide mixture in a binder. The last layer is the negative current collector, which is a conductive copper paint diluted using ethanol.

Singh informed that the separator was the key to achieve the required mechanical stability. The researchers discovered that the cathode and nanotube layers were adhered well; however, they would detach from the substrate if the separator lacks mechanical stability. Once coated, the substrates were subjected to electrolytic infusion, followed by heat-sealing and charging.

The Rice research team has submitted a patent application on the method, which they will improve further. The team is seeking electrolytes that would allow the creation of painted batteries in the outdoor. It also envisages the paintable batteries as snap-together tiles, which can be arranged in different ways.