Feb 16 2006

Topics Covered

Background

Tribology

Lubricants

Friction and Wear

Studying Nanoscale Tribology

Materials Suited For Analysis

Nanoscale Wear Analysis

Lubricant Studies

Frictional Forces

Simultaneous Measurement of Topography

and Friction Forces

Surface Texture / Morphology / Roughness

Nanoscale Mechanical Properties

Background

Tribology

The term tribology is derived from

the Greek word "tribo" meaning rubbing and "logy" meaning knowledge.

The original applications by the Greeks of tribology were in trying

to understand the motion of large stones across the earth's surface.

Today tribology has grown to include the methodical study of friction,

lubrication, and wear.

Tribology plays a critical role

in diverse technological areas. In the advanced technological industries

of semiconductor and data storage, tribological studies help optimize

polishing processes and lubrication of data storage substrates. In

traditional industries such as automotive and aerospace, tribological

studies help increase the lifespan of mechanical components.

Lubricants

Many industrial processes require

a detailed understanding of tribology at the nanometer scale. The

development of lubricants in the automobile industry depends on the

adhesion of nanometer layers (mono layers) to a material surface.

Assembly of components can depend critically on the adhesion of materials

at the nanometer length scale.

Friction and Wear

There are a number of traditional

tools for characterizing friction, lubrication and wear. The most

common characterization tool is the tribometer having several configurations

such as pin-on-disk, ball on flat, and flat on flat, etc. Generating

motions at the nanometer scale is extremely challenging. New characterization

techniques are required to understand tribology at the nanometer scale.

Studying

Nanoscale Tribology

The atomic force microscope is now

being routinely applied for studying nanoscale tribology. The natural

extension of the AFM for tribology applications is derived from the

motion of a nanometer-sized stylus in the AFM over a surface. Although

traditional tribology testing is not done with an AFM, many new types

of applications are possible.

Examples of the application of AFM

to tribology include:

- Direct three-dimensional visualization of wear tracks, or scars on a surface.

- Measurement of the thickness of solid and liquid lubricants having nanometer

or even monolayer thickness.

- Measurement of frictional forces at the nanometer scale.

- Surface characterization of morphology, texture, and roughness.

- Evaluation of mechanical properties such as hardness and elasticity, and

plastic deformation at the nanometer scale.

Materials

Suited For Analysis

A major advantage of the AFM for

tribological studies is that the AFM can be routinely used on all

types of materials. Materials commonly studied include: ceramics,

metals, polymers, semiconductors, magnetic, optical, and biomaterials.

AFM investigations are usually made in ambient air environment. It

is possible to make AFM studies in a vacuum or liquid environment.

Nanoscale

Wear Analysis

The effects of wear at the nanometer

scale become critical to the optimization and stability of machines

as the tolerances in precision machines become smaller and smaller.

Traditional microscopes such as the optical and scanning electron

microscopes facilitate visualization of wear in 2-dimensions. For

example, with the SEM it is possible to get a magnified view of wear

tracks in the x-y axis but cross sectioning is required for measuring

the depth of wear tracks.

The AFM allows direct 3-dimensional visualization of wear tracks and scars.

The images may be displayed in a 2-D projection and a 3-D projection. Direct

measure of wear track depth can be easily measured with a line profile derived

from the AFM image.

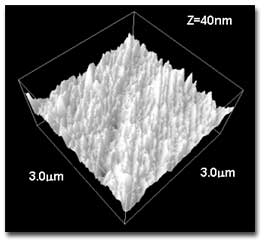

Figure 1. Three-dimensional atomic force microscope (AFM)

image of a polish mark on a piece of steel. The scan range in X and Y is 3 micrometers

and the entire Z range is 40 nanometers.

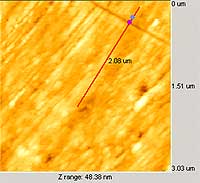

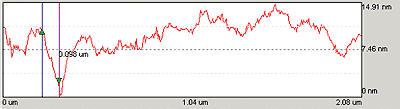

Figure 2. Metrological study of a scratch mark in the

surface of a polished material (stainless steel). Because the AFM directly measures

three-dimensional data, the depth of the scratch mark is easily quantified.

In this case the mark is 8.6 nm deep. Z= 8.6 nm

Lubricant Studies

It is well known that layers of

lubricants on surfaces that are less than 100 nm can dramatically

affect lubrication behavior. Characterization of such films is necessary

for developing optimized lubricating films. However, nanometer scale

characterization of lubrication films offers a substantial challenge.

Optical techniques such ellipsometers can be used for measuring lubrication

thickness of large sections, (greater than 10 square micrometers),

of a surface. Measurement of the localized (less than 1 micron) film

thickness is not possible with the ellipsometer.

The probe is mounted at the end

of a cantilever in an AFM making it possible to measure interaction

forces between the probe and the surface by monitoring the deflection

of the cantilever. A graph, called a force/distance curve, shows the

forces on the probe as the distance between the probe and the surface

are reduced. The nature of the force/distance curve depends on the

force constant of the cantilever, the lubrication density, probe geometry,

and the lubrication thickness.

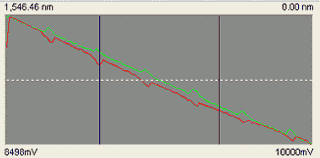

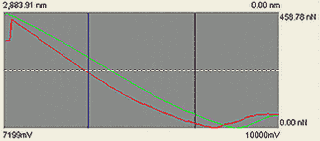

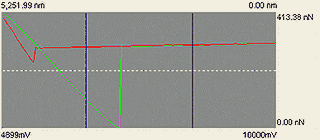

By measuring the changes in force/distance curves in an AFM it is possible

to directly ascertain the thickness of lubrication films. Below is an example

of a force/distance curve for a surface with no lubrication film compared to

one with a lubrication film. The thickness of the film is established from the

force/distance curve.

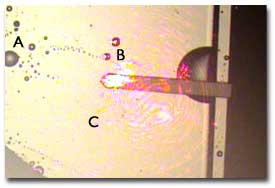

Figure 3. Video optical microscope image of a silicon

surface coated with a lubricant. Force/Position curves were measured at locations

on the surface indicated with the letters A, B, and C. The red light in the

video microscope image is from the laser used for the force sensor in the atomic

force microscope.

A: Force/Position curve measured on one of the droplets of lubricant.

The slope represents the force required to move the AFM probe through the liquid

surface.

B: Force/Position curve at a place on the surface where there

is apparently a thin film of lubricant material.

C: Force/Position curve on a section of the silicon surface

that appears to have no lubrication.

Frictional Forces

Friction between two surfaces depends

on the chemical and mechanical interaction between the surfaces. Changes

in chemical composition giving rise to friction are measurable with

the AFM. The technique for measuring these forces is called lateral

force, or frictional force microscopy.

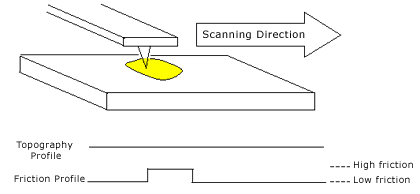

As the probe moves over a surface in the AFM, changes in the chemical composition

of the surface can give rise to torsions of the cantilever on which the probe

is mounted. The torsion of the cantilever is then proportional to the friction

between the probe and the surface.

Figure 4. Illustration of the principle that allows lateral

force or frictional fore microscope images to be measured. The cantilever will

twist as the probe interacts with the surface while scanning.

Simultaneous Measurement of Topography and Friction Forces

In an AFM it is possible to simultaneously

measure topography and frictional force images. The topography image

is derived from monitoring the vertical forces on the cantilever and

the friction image is acquired simultaneously by monitoring the lateral

motions of the cantilever. Below is a FFM image of a sample illustrating

changes in the friction.

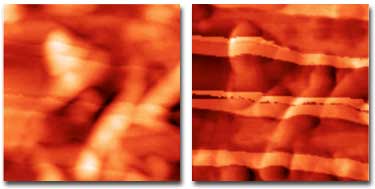

Figure 5: (left) Two dimensional view of a

composite material measured with the AFM. Barely visible in this image are striation

marks derived from a change in chemical composition at the surface. (right)

The lateral force or frictional force image of the composite material clearly

shows changes in chemical composition at the surface of the composite material.

Both the topography and frictional force image are measured simultaneously with

the AFM.

Surface

Texture / Morphology / Roughness

The AFM gives extremely high contrast on surfaces that are flat at the nanometer

scale. Optical and electron microscopes are not able to resolve surface texture

that is easily measured with the AFM. Applications include the visualization

of surface topography in both 2-d and 3-d perspectives, line roughness measurements,

and area roughness measurements. All of the traditional area and surface roughness

parameters can be calculated after the AFM image is acquired.

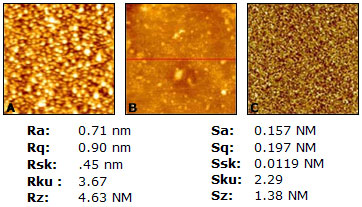

Figure 6. (A) AFM image of a metal bonding pad on a semiconductor

device (B) Use of the AFM to measure line roughness of a polymer sample (C)

AFM image of polished silicon and the area roughness of the silicon.

Nanoscale

Mechanical Properties

Mechanical properties such as hardness,

elastic modulus, stiffness and compressibility as well as material

behavior such as plastic deformation, and fracture can be studied

with the AFM.

It is possible to study nano-hardness by directly pressing an AFM probe into

a sample's surface; however, it is advantageous to use an instrument that is

optimized for nano-indentation. The primary advantage of the nano-indenter over

an AFM for nano-hardness measurements is that it is easier to get calibrated

measurements with the nano-indenter. It is useful to use the AFM to measure

the three-dimensional topography of indentations made with a nano-indenter.

AFM images allow direct visualization of material deformation or fracture behavior.

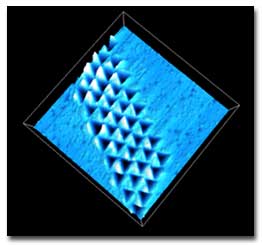

Figure 7. Three-dimensional view of nano-indents in a

material surface. From the AFM image it is possible to see the depth of the

indentation as will as visualizing the material deformation.

Using techniques such as pulsed

force mode, the stiffness of a sample at a matrix of locations is

measurable. From this data it is possible to create a stiffness mapping

of a surface. Stiffness maps can only be made on samples where the

stiffness of the surface is lower than the stiffness of the cantilever.

Such stiffness images are routinely measured on polymer samples.

Adding a fixture to the stage of

the AFM makes the study of material behavior such as plastic deformation

and fracture possible. The fixture permits creating forces on a sample

while AFM images are being taken. A variety of materials may be studied

with such a technique.

The following information was supplied by Pacific Nanotechnology