|

Just as the key building block to life on earth is the carbon atom, carbon is the key to one of the most promising branches of nanotechnology. Much of the current research and commercialisation of nanotechnology relies on tubes, wires and balls made from carbon atoms. All are known by a number of names. The carbon based tubes can be carbon nanotubes, buckytubes and very long tubes are often referred to as nanowires. The balls are known as fullerines or buckyballs.

History of Buckytubes and Buckyballs

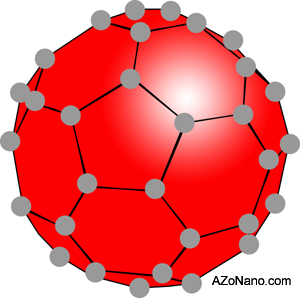

Russian researchers discovered carbon nanotubes in the 1950s but the research was only published in Russian and the Cold War meant this information was not widely available. In the 1980s knowledge surrounding carbon nanotubes and balls become more widespread. The balls resembled the geodesic dome shape designed by American, R. Buckminster Fuller, and the buckyball or fullerene was named in his honour. The simplest form of buckyball is the C60 Buckminsterfullerene. A shape instantly recognisable for it’s soccer ball like features. An adaptation of the method for producing buckyballs produces cylindrical buckytubes.

Figure 1. C60 variant of a buckyball

Buckytubes

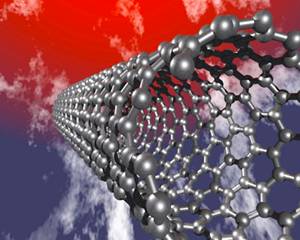

Buckytubes or carbon nanotubes are basically buckyballs that have not closed over to form a sphere. Carbon nanotubes can be single walled carbon nanotubes (SWNT) or multiwalled carbon nanotubes (MWNT) but it is SWNT that are most commonly used at this point in time. Typical carbon nanotubes are around 1nm in diameter and several hundred nanometers long – even several millimetres long.

Figure 2. A single walled carbon nanotube

Making Carbon Nanotubes

Like buckyballs, carbon nanotubes are produced naturally in the soot produced by burning many chemicals and compounds. These naturally occurring carbon nanotubes are highly irregular in size and are mixed with an unacceptable amount of normal carbon soot. In order to be viable for research or commercial applications quantities of high quality uniform nanotubes are required.

Initially, researchers found that a simple addition of a small amount of vaporised nickel nanoparticles to the carbon arc or laser vaporisation methods used to produce buckyballs would produce carbon nanotubes. The carbon would dissolve into the nickel to a saturation point after which carbon would deposit on the surface of the nickel nanoparticles. From these carbon atoms grow nanotubes as the anchoring site with the nickel nanoparticle doesn’t allow for the buckyball to seal over into a sphere. Although effective in producing carbon nanotubes, these relatively expensive methods produce a low quality mix of short length SWNT and MWNTs combined with carbon soot.

Commercially viable methods for producing carbon nanotubes include high pressure carbon monoxide (HiPco), chemical vapor deposition (CVD) and a plasma enhanced process.

High Pressure Carbon Monoxide (HiPco)

High Pressure Carbon Monoxide (HiPco) processing uses a flow of carbon monoxide gas and clusters of iron through a heated chamber. The iron acts as a catalyst to split the carbon monoxide into carbon and oxygen. Some of the atoms recombine to form carbon dioxide and the remaining carbon atoms bond together into a nanotube lattice.

Chemical Vapour Deposition (CVD)

Chemical Vapour Deposition (CVD) of carbon nanotubes uses a metal catalyst coated substrate in a heated chamber. The size of the metal catalyst particles determines nanotube diameter. Two gases are introduced to the chamber; a process gas like ammonia, hydrogen or nitrogen and a hydrocarbon gas like acetylene, ethylene, methane or ethanol. At temperatures in excess of approximately 700°C the carbon atoms break from the hydrocarbon gas. Carbon atoms attach to the catalyst particles and other carbon atoms bond to it forming a nanotube.

Plasma Enhanced Chemical Vapour Deposition

Plasma enhanced chemical vapour deposition is similar to CVD but passes the hydrocarbon gas through a plasma field. The nanotubes formed grow in the direction of the electric field used to generate the plasma. Catalysts used and other details are a closely guarded secret as this method is claimed to produce a vast quantity of high quality nanotubes.

Properties

The extraordinary properties of carbon nanotubes is what makes them suited to a wide range of applications. The properties of carbon nanotubes include extremely high tensile strength, elasticity, flexibility and high thermal conductivity. Depending on the structure of the nanotube, they can be either be electrically conducting like metals or semiconducting.

Applications

Carbon nanotubes are already incorporated into polymers and other materials to create composite materials with improved electrical, mechanical and thermal properties. These composite materials are used in applications diverse as sporting equipment, clothing and ballistic armour.

Other areas where carbon nanotubes can be used include various electronics. Nanowires made from carbon nanotubes can allow electrons to travel ballistically through them – that is without encountering resistance.

|