| The groundbreaking work of nanotechnology researchers rarely rates a mention in the mainstream media. Occasionally their work includes a quirky side that fires the imagination of news broadcasters and our televisions and newspapers show oddities ranging from nanosized musical instruments to working nanosized cars. Although interesting to people outside the scientific community, these developments also have a serious side. Nanoguitars and Other Nano Sized Instruments In 1997 Cornell Univeristy researchers cut a solid body guitar from a single crystal of silicon. The 10 micron long Fender Stratocaster replica guitar was superseded in 2003 when researchers from the same facility built a new guitar. This version was a replica of a Gibson Flying V and had playable strings. Although around 5 times larger than the original guitar the only way to play the strings with a laser. Too high for human ears to hear, the notes were 17 octaves above that of a normal guitar.

Figure 1. Cornell University image of the original nanoguitar

Figure 2. Playable Flying V nanoguitar from Cornell University Since then other musical instruments have been created on the nanoscale. These have included nanoharps, nanodrums and nanoxylophones. Practical Applications of Nanoguitar Technology By understanding how tiny things vibrate at high frequencies, a range of potential applications in advanced electronics are opened up. Currently wireless electronic devices like cell phones use quartz crystals to oscillate and generate a carrier signal. Tiny nanorods could be used in place of the crystal to produce even smaller devices that use only a fraction of the power. Plucking the strings of the nanoguitar with a laser can be adapted for using nanotechnology to modulate laser light in fibre-optic communications systems. This could reduce the complexity and expense of such systems bringing fibre-optic connections into the home and between desktop computers. Nanocars In late 2005 scientists from Rice University developed the Nanocar. This initial vehicle consisted of a chassis, axles and wheels and was only around 3-4 nanometers across. The chassis and axles were made from organic molecules and the wheels from buckyballs.

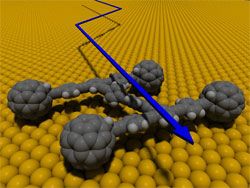

Figure 3. The original Rice University nanocar The nanocars rolled on a heated gold ‘road’ and were unpowered but moved by pushing with either an electromagnetic field or an STM probe tip. The gold road had to be heated to stop the buckyball wheels sticking to the road. Nanocars With Engines About 6 months after developing their initial nanocar the Rice researchers added a motor to the nanocar. They used a light powered rotating motor based on molecular framework developed at the University of Groningen. Light striking the motor causes it to rotate in one direction like a paddlewheel. This in turn pushes the car along. This car uses independently spinning alkyne axles but the buckyball wheels were found to drain energy from the motor. They were replaced with spherical p-carborane molecules of carbon, hydrogen and boron. Nanotrucks and Other Nano Sized Vehicles The original Rice University nanocar concept is now being greatly expanded upon. New nanosized vehicles that have been made include nanotrucks with the ability to carry a payload, a six wheeled NanoCaterpillar, nanotrains and a nanobackhoe that has a flexible arm that can be extended. Even smaller nanocars have also been developed. New research is focussed on the development of a high performance sports car version of the nanocar. This vehicle is to have two solar powered motors. Fully Functioning Nanocars Nanocars with all the features of a modern passenger vehicle have also been reported. Just as full sized cars are built from a range of components made by different companies and subcontractors, these nanocars are a collaboration between various companies, researchers are their areas of expertise. These cars are many times larger than the Rice University vehicles but all their components are nanotechnology based. One such car uses an electrostatic motor and gearbox powered by solar cells and controlled by an onboard neural net computer. The wheels are driven by a nanochain connected to the motor and braking is provided by electrostatic disc brakes. Wheels are buckydiscs with spokes of stem cell nanotubes. The car body is made from carbon nanotubes. Applications of Nanocar Technology Building a nanocar is not a simple matter of bolting parts together. A key component of nanocar construction is understanding how molecules interact with each other. Understanding these interactions is the key to bottom up construction, molecule by molecule. Functional and reliable nanocars could also be used to transport material on a nanoscale to build other nanomachines and structures. |