A composite of graphene and polyurethane could be the key to a boost in effiency for vehicles running on compressed natural gas (CNG) , and improve the shelf life of bottled beer and fizzy drinks.

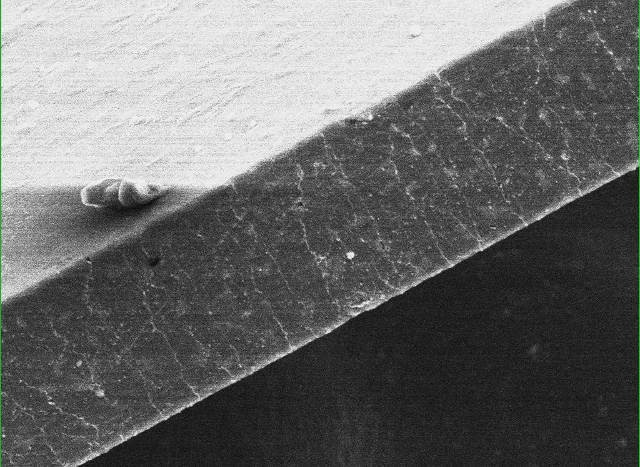

A close-up cross section of graphene nanoribbon-enhanced polymer shows the ribbons as white dots dispersed through the material, where they effectively block gas molecules from passing through. Image credit: Changsheng Xiang/Rice University

James Tour's research lab at Rice University in Houston is one of the most prolific graphene research groups - their recent work includes integrating graphene into carbon fiber, developing computer memory made from graphene and silicon oxide, and boosting the efficiency of lithium ion batteries using graphene nanoribbons.

Today, they announced a breakthrough material which could help make natural gas powered cars much more efficient - potentially helping the automotive industry to deliver on the current push towards CNG fuel as a mainstream alternative to gasoline.

The new composite material utilizes one of the many attractive properties of graphene - its impermeability to gas.

CNG fuel tanks currently have to be made out of thick, bulky metal in order to properly contain the gas, which can leak straight through plastics and polymers.

Graphene's unique ability to contain gas allows it to solve this problem - lining a lightweight polymer tank with graphene would create huge fuel efficiency benefits without compromising on safety.

However, manufacturing a high-quality sheet of graphene large enough to cover a fuel tank is no simple task, and will probably remain out of reach for some time.

Tour's group have come up with a different solution - using overlapping graphene nanoribbons (GNRs) dispersed through a polymer instead of a single continuous sheet.

Their research shows that thermoplastic polyurethane laced with 0.5% GNRs is very nearly as effective at preventing gas from escaping the tank, and the GNRs are vastly easier to produce and work with than large graphene sheets.

Back in 2009, the Rice researchers developed a method to create GNRs by "unzipping" carbon nanotubes to produce flat strips - a method which has now been licensed for use on an industrial scale. Prof. Tour is confident that bulk production of the nanoribbons will prevent the cost of the graphene-enhanced fuel tanks from becoming too high.

Another potential application for this graphene composite is in drinks packaging - as the gas permeability problem is also an issue for manufacturers who want to store carbonated drinks in plastic bottles:

"Once, you couldn’t get a carbonated drink in anything but a glass bottle, until they figured out how to modify plastic to contain the carbon dioxide bubbles. And even now, bottled soda goes flat after a period of months.

“Beer has a bigger problem and, in some ways, it’s the reverse problem - oxygen molecules get in through plastic and make the beer go bad. Bottles that are effectively impermeable could lead to brew that stays fresh on the shelf for far longer."

- James Tour

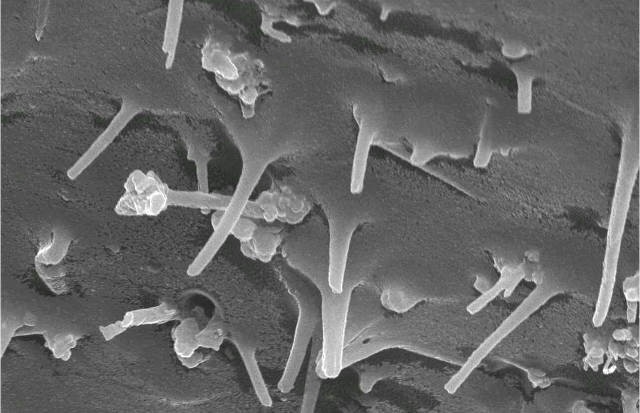

An electron microscope image showing graphene nanoribbons embedded in a block copolymer. Image credit: Tour Group/Rice University

References and Further Reading