Image credit: billdayone/Shutterstock.com

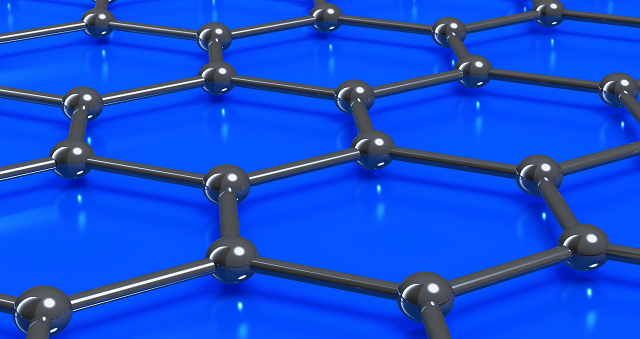

The successful fabrication of single layered graphene has generated a great deal of interest and research into graphene in recent years. One of the most recent advancements is the development of graphene nanoribbons (GNRs) layers of graphene with ultra-thin width of less than 50 nm.

GNRs were originally discovered by Mitsutaka Fujita whilst examining the nanoscale size and edge effects of graphene. These structures exhibit semi-conducting and metallic electronic structures with band gaps that can be tuned across wide ranges. Certain nanoribbons have gapped magnetic phases through which a semi-metallic state can be induced.

Structure of Graphene Nanoribbons

GNRs have inherited almost all of the attractive properties of graphene and carbon nanotubes, with an additional advantage of having a tunable band gap.

The controlled edge orientation of GNRs has been studied using a scanning tunneling microscope (STM). Studies revealed that the electronic states of GNRs mainly depend on the edge structures – armchair or zigzag structures.

Experiments based on tight binding theory suggested that armchair-edge structures are always either metallic or semiconducting and zigzag-edge structures are always metallic, with respect to their width. Opening of energy gaps was reported to be up to 0.5 eV in an armchair-edge GNR having a width of 2.5 nm.

Zigzag-edge GNRs open with respect to the anti-ferromagnetic coupling between the carbon atoms of opposite edges. The gap size of zigzag-edge GNRs is inversely proportional to the width of the GNR.

Moreover, GNRs possess low noise, and high thermal and electrical conductivities which make them a potential alternative to copper in integrated circuit interconnects.

Production of Graphene Nanoribbons

Large amounts of width-controlled GNRs are produced through a process called graphite nanotomy. In this process, graphite is cut with a diamond knife to produce graphite nanoblocks which are then exfoliated to produce GNRs.

Another production method involves unzipping or cutting multi-walled carbon nanotubes in a solution with the help of sulfuric acid and potassium permanganate. Plasma etching of nanotubes partly embedded in a polymer film also produces GNRs.

Researchers have also proposed a method of growing GNRs on silicon carbide substrates using ion implantation followed by laser or vacuum annealing.

Most recently, Tohoku University developed a new method to produce defect-free GNRs. Their bottom-up fabrication method produces GNRs with periodic zigzag-edge regions.

Applications of Graphene Nanoribbons

GNRs are commonly used in the following applications:

- Field effect transistors

- Schotkky diodes

- P-N junctions

- Light emitting diodes

- Solar cell systems

- Liquid crystals

- Transparent conductive electrodes

A Big Future for Nanoelectronics

GNRs are considered as one of the most promising models for future nanoelectronics. Due to their unique structure and properties, GNRs are widely used in a large number of applications, from spin and valley filters to chemical sensors.

However, researchers feel that the fine-tuning of the electronic band gap of GNRs will increase GNR's future potential applications. They also hope that fabricating high-quality GNR samples with accurate control of the edge structures will stimulate the progress of research on GNRs.

References

- Electronic Band Structure of Armchair and Zigzag Graphene Nanoribbons – Wolfram Demonstrations Project

- GRAPHENE NANORIBBONS – University of South Carolina

- https://www.natureasia.com/en