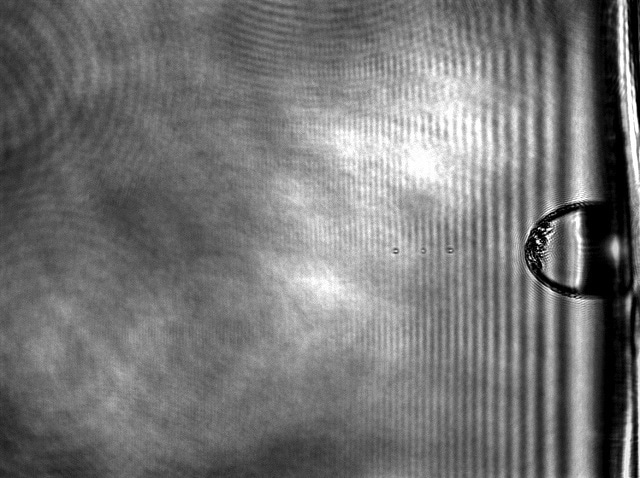

A micro bullet traveling at supersonic speed is captured in this composite of three timed images, as it makes its way toward a suspended sheet of multilayer graphene. Experiments carried out at Rice University show graphene is 10 times better than steel at absorbing the energy of a penetrating projectile. The bubble at left is a polymer film expanding away from the gold substrate that transfers energy from a laser to the micro bullet. Image Credits: Thomas Research Group

Soldiers, police, and others who put themselves in harm's way depend on Kevlar and other fabrics to spread the impact of projectiles and allow them to perform their jobs in relative safety, but bulletproof materials still need to be continually tested and improved. Researchers from Rice University have used micro bullets to analyze graphene strength and feasibility in these applications.

Bullet-Proof Nano

Most anti-ballistic materials used in bullet-proof jackets or explosion-proof blankets are made of Kevlar, Twaron or Dyneema fibers, which stop bullets from penetrating the surface by spreading and absorbing the impact of the bullet's force. These products were a significant step forward, but often still result in the target suffering from blunt force trauma, severe bruising or damage to vital organs. This is because the force from the bullet reaches the wearer even when the bullet itself is stopped.

Researchers from Rice University have demonstrated that firing microscopic projectiles at multilayer graphene sheets provides a measure of difficulty for penetration of graphene on the nanoscale. Using high-speed cameras, the team were able to capture detailed images of the projectiles penetrating sheets and determined that graphene acts like a stretchy membrane, distributing the bullets energy over a large area.

Microbullet hits confirm graphene's strength at Rice University

Video Courtesy of Rice University YouTube Channel

Research has often focused on graphene’s electronic properties and tensile strength, but this new finding shows graphene’s ability to be stiff, strong, and elastic simultaneously. These characteristics could offer applications in body armor and aerospace shielding.

Carbon Nanotubes

A team of researchers from the University of Wollogong have succeeded in developing a new graphene composite material which is stronger than spider silk and Kevlar.

Finding the optimal ratio of graphene to carbon nanotubes is a key factor in the development of bullet proof composites. The new graphene composite can be fabricated easily using a wet-spinning method, producing fibers with potential applications in bullet proof armor and reinforcement materials.

Beehive

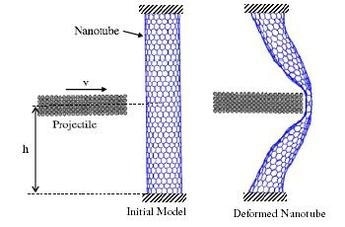

Carbon nanotubes have also been used extensively in the pursuit for nano-bulletproof materials. With a beehive shaped structure and cylindrical nature, these nanotubes have demonstrated incredible strength. They are capped at each end and linked together with covalent bonds to produce nanofibers hundreds of times stronger than steel. The bonds themselves are stronger than those found in diamonds, the hardest substance known to man.

The molecular dynamics model of a carbon nanotube subjected to ballistic impact. (a) The initial model, (b) A deformed (18, 0) nanotube at its maximum energy absorption. Image Reference: Dickinson College

The resulting carbon nanotubes are light, flexible, strong, and thermally-stable. In a bullet proof vest, millions of these nanotubes come together to form carbon nanofibers which are woven together to create lightweight material. The resulting carbon nanofibers are extremely efficient at absorbing energy, making them ideal for bullet proof armor.

A team from the Centre for Advanced Materials Technology at the University of Sydney have already created a material capable of absorbing the force of a bullet using these materials. In the market the Garrison Bespoke bulletproof suits is available, producing a similar performance. The suit uses a thin patented carbon nanotube material which sits between its lining, protecting the owner from stabbings, bullets and any other projectiles which may cause harm.

Conclusion

There are many potential applications for bullet proof nanomaterials, but they still face challenges.

The primary concern with graphene nanotechnology thus far has been creating adequate tests of the materials prior to field testing. Current tests provide little reliable evidence of the material's strength when used to defend against high-speed projectiles.

Researchers from the University of Massachusetts - Amherst devised a ballistics test that tested graphene nanotubes against superheated vaporized laser pulses, which acted like gunpowder to fire a micrometer-size glass bullet into 10 to 100 sheets of graphene at 3 kilometers per second, about three times the speed of a bullet fired from an M16 rifle. The result of these tests showed that the graphene nanotubes absorbed the impact by stretching into a cone shape at the point of the bullet's strike, then cracking outward. These cracks are perceived to be the material’s main weakness; despite this, the material still performed better than Kevlar and absorbed 10 times the kinetic energy achievable with steel. Assembling multiple layers of the graphene material or combining them into a composite material is expected to solve this problem.

Sources and Further Reading

This article was updated on the 12th April, 2019.