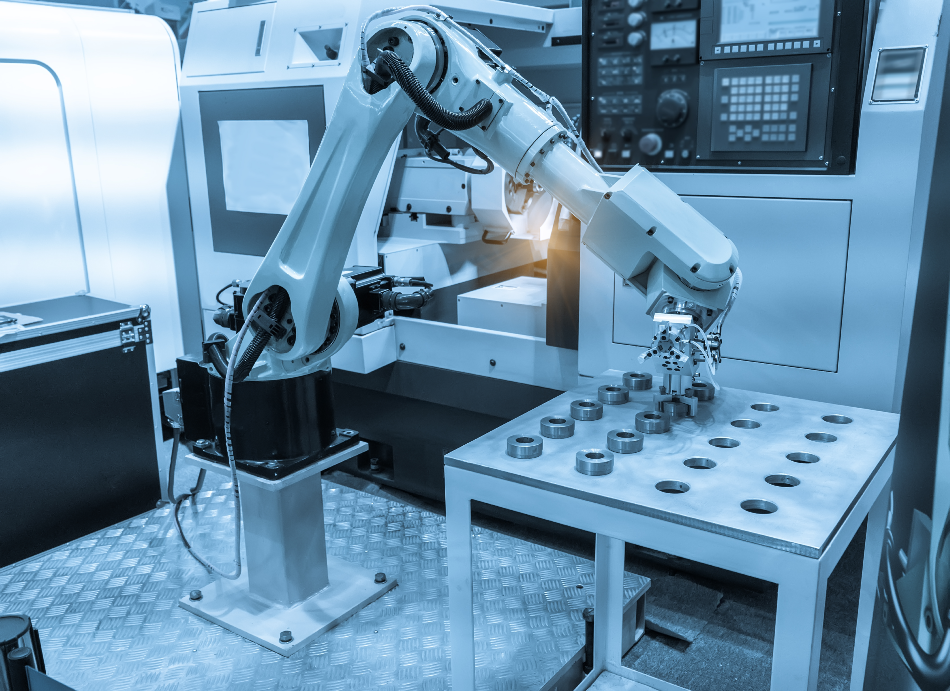

asharkyu / Shutterstock

Used to cut, mill and grind materials for fabrication purposes, the CNC machine has been the workhorse of industrial machining. However, these machines are slowly being replaced by robotics.

Robotic machining is known as a viable alternative for fashioning metal and non-metal materials, with the ability to process the latter based on hardness, geometric intricacy, physical tolerance, and desired surface finish. Recent technical advances have led to the improved mechanical ability of industrial robots and faster production speeds, which has expanded their use.

Industrial Robots

The use of robotics in manufacturing is continuously growing around the world and predictions indicate that their use will carry on expanding. While the sale of robots saw a massive setback due to the global economic crisis of 2009, sales have since rebounded significantly according to a recent study.

The sales of industrial robots rose by nearly 40 percent in 2011, caused primarily by the automotive and metalworking industries. Nearly 80 percent of industrial robotics sales are for material handling and welding activities, while the percentage of sales for machining operations is lower than 5 percent of overall sales. However, those figures could grow as machining robots can be used in many different industrial sectors and operations.

Machining Robots

Machining robots use a tool center point (TCP) to carry out various operations; similar to the way a CNC machine manipulates various tools. For instance, by manipulating the pressure of a surfacing tool operating on a workpiece, machining robots have been used to perform finishing tasks like grinding, polishing and deburring, all of which are operations traditionally conducted manually.

Importantly, machining robots are able to operate in three, four or five axes. Numerous recent improvements in the technology have made machining robots a competitive alternative to both manual labor and CNC machines.

Specifically, increased tool positioning capability; greater work areas and volumes; and cost reductions up to 50 percent have all made machining robotics more competitive. Furthermore, add-on capabilities, such as a computer vision system or enhanced pressure control, can significantly enhance the functionality and versatility of a machining robotic cell, but also increase the cost.

Advantages of Machining Robots

Both CNC machines and machining robots can be costly. However, robots have two major benefits that can make them a more attractive option: a larger workspace and greater versatility. These advantages allow machining robots to work with items of almost any shape, size, and complexity.

Although there are very large CNC machines, they have a fairly small workspace. Industrial robots, conversely, have a much larger workspace. For instance, a moderately-sized machining robot has a working volume of 7 to 8 cubic meters. Moreover, an external axis can be readily added to a machining robot, extending its workspace even further.

A different main advantage of machining robotics is their flexibility. Most systems can readily be moved from one task to another. CNC machines are excellent at performing one particular task at a time, whether it's cutting, drilling or milling. A machining robot can do all of the same functions as a CNC machine, and more.

Conclusion

Robots are capable of working along more intricate work paths than the typical CNC machine. CNC machines also typically have 3 or 4 different degrees of motion. This is adequate for many machining jobs, but it can be prohibitive. Nearly all industrial robots have 6 degrees, enabling the creation of almost any shape.

Machining robots can also be much less expensive. Scientists from the University of Mons in Belgium recently estimated that a robot is 30 percent less expensive than a machine tool with a similar workspace.

Sources

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.