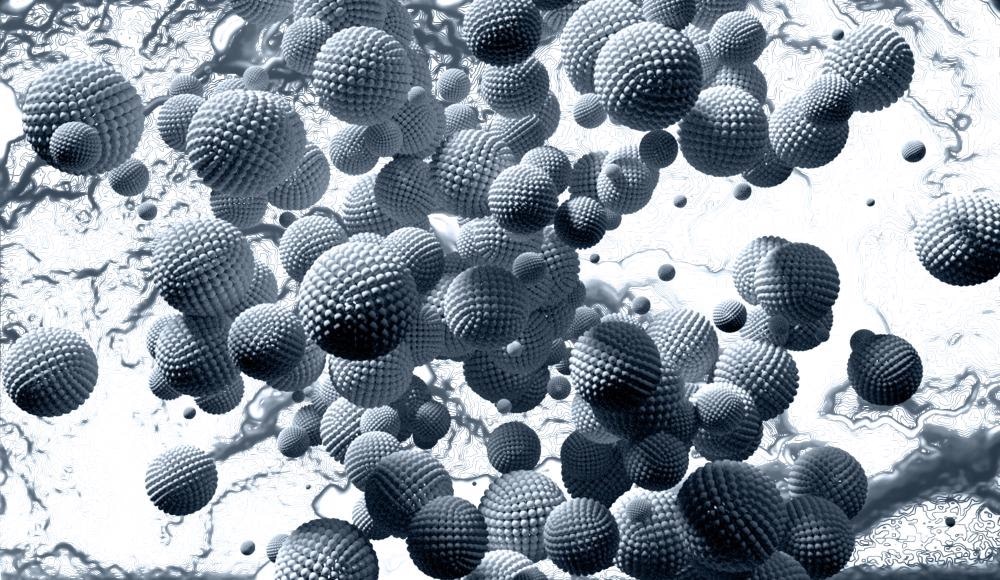

Image Credit: GiroScience/Shutterstock.com

New research suggests a method to improve the large-scale production of single-walled carbon nanotubes vital for increasingly sophisticated electronics.

The production of single-walled carbon nanotubes (SWCNT) has come a long way in the last few years, developing from physical methods such as arc-discharge and laser ablation to a convenient chemical vapor deposition (CVD) approach — a method used in industry to create a thin film of a substance. Films do not get any thinner than SWCNTs, which are made from rolled tubes of graphene sheets just a single carbon atom thick.

New research published in the Chemical Engineering Journal puts forward a quicker, simpler, and more efficient way of producing these tiny rolled graphene sheets, developed by researchers at Skoltech Institute of Science and Technology, Moscow. The paper details a completely different approach to boosting efficiency in the production of SWCNTs, focusing on an aspect of their creation that is not often considered.

The team found a 9-fold increase in production of the nanotubes with little loss of essential characteristics such as film conductivity and diameter when the catalyst injection process was refined. The method could allow for more wide-scale production of SWCNTs — which hold great promise in electronics and material sciences.

Shaping the Future with Nanotubes

Nanotubes inherit their electrical properties from the thin layers of graphene rolled to create them. In addition to this, they also have unique thermal and mechanical properties, all while being chemically stable and incredibly lightweight.

All these properties make nanotubes ideal for use in many applications, including:

- Electronic devices

- Biosensors

- Transistors

- Electron field emitters

- Lithium-ion batteries

- White light sources

- Hydrogen storage cells

- Cathode ray tubes (CRTs)

- Electrostatic discharge (ESD)

- Electrical-shielding

With widespread applicability in such profitable commercial fields, it is of little wonder that carbon nanotube and graphene creation, in general, is such a hot area of research for material scientists.

The problem is that while methods of extracting graphene from graphite are fairly easy for tiny amounts , scaling up these methods’ results is challenging.

Albert Nasibulin, a professor at Skoltech and an adjunct professor at the Department of Chemistry and Materials Science, Aalto University School of Chemical Engineering, explains that crafting SWCNTs from raw materials is a complicated process and one that is not yet fully understood - something he and his team aimed to change.

A Catalyst for Improved Carbon Nanotube Creation

The CVD method uses metal catalyst particles to remove carbon atoms from gas to grow nanotubes on a wafer substrate.

There is a multitude of different ways to carry out this process. Most modern CVD approaches use low-pressure or an ultra-high vacuum to limit unwanted gas-phase reactions and improve film uniformity across the wafer. However, Nasibulin and his team took an entirely different approach, adopting the established aerosol-assisted injection CVD (AACVD) method.

The AACVD — or floating catalyst — technique takes place in a high-temperature furnace or reactor, into which precursors are transported to the substrate using a liquid/gas aerosol, which can be generated ultrasonically.

The AACVD approach is considered to be most promising in the production of SWCNTs because of its scalability and the fact it can be performed without additional time and resources.

The Skoltech team aimed to improve the injection procedure and better distribute a catalyst precursor — a substance that can be activated to yield a catalyst — within the reactor. The team used Ferrocene vapor, a commonly used catalyst precursor in AACVD techniques, and carbon monoxide as a carbon source in its study.

Dmitry Krasnikov, a senior research scientist at Skoltech and co-author of the paper, points out that the activation of catalysts — substances that speed up chemical reactions without being changed themselves — is an area of AACVD and SWCNT production that has not been widely studied and refined for efficiency.

The team addressed one of the significant drawbacks of the AACVD method: it is difficult to activate a large proportion of the catalyst molecules. The fact that many of these particles do not contribute to the growth of nanotubes reduces the final yield, as well as negatively affecting the size of the final material.

The team found that the rate at which catalysts were delivered by adjusting the injector's width positively impacted synthesis efficiency , producing more SWCNT. The nanotubes produced were not affected in terms of quality by this adjustment, displaying consistent diameter and film conductivity, with the same amount of defective product.

The CVD process currently holds the most significant promise for nanotube production, and this development could see the mass production of carbon nanotubes become bigger, cheaper, and faster.

References and Further Reading

Khabushev. E.M., Kolodiazhnaia. J. V., Krasnikov. D. V., Nasibulin. A. G., [2020], ‘Activation of catalyst particles for single-walled carbon nanotube synthesis,’ Chemical Engineering Journal, doi.org/10.1016/j.cej.2020.127475

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.