AZoNano speaks to Dr. Jinian Yang about recent research investigating the effects of introducing flower-like nickel phyllosilicate nanoparticles into epoxy resin. This epoxy nanocomposite reported increased mechanical strength and a positive impact on thermal and tribological properties, which may help pave the way for a new industry standard of epoxy resin.

Please could you introduce yourself and tell us what inspired your career with nanomaterials?

I worked as a teacher at Anhui University of Science and Technology for some time, but my current interests are in polymeric materials and engineering. My involvement with nanomaterials began when I introduced nanomaterials with various functions into a polymer matrix, which yielded functional nanocomposites.

How did you begin your involvement with research into epoxy resin?

Because my present major is closely related to polymer materials, I found epoxy was a popular resin.

Pure epoxy resin (EP) is characterized by many superior features; however, it suffers from intrinsic issues such as brittleness. We hope to improve such drawbacks, which are particularly applicable for practical applications.

Could you provide a brief explanation of why there is a need to improve epoxy resin's mechanical, thermal, and tribological properties? What role does nanotechnology play in this?

Epoxy is characterized by a high three-dimensional network construction and high crosslinking density, resulting in poor tribological features, especially under dry sliding. The friction process of materials is a complicated process involving their mechanical strength, thermal resistances, amongst other properties of EP. Improving these aspects is, therefore, necessary to enhance EP for practical applications.

Nanotechnology may provide a solution to this problem as various nanomaterials could play different roles in the enhanced performances of epoxy resin. For example, nanofiller can improve the tensile properties effectively, while nanoparticles are more suited to enhancing compressive performance.

Nevertheless, if the addition of nanomaterials can provide abundant interactions between different phases, reinforcements will be evident in improving the mechanical, thermal, and tribological properties of EP.

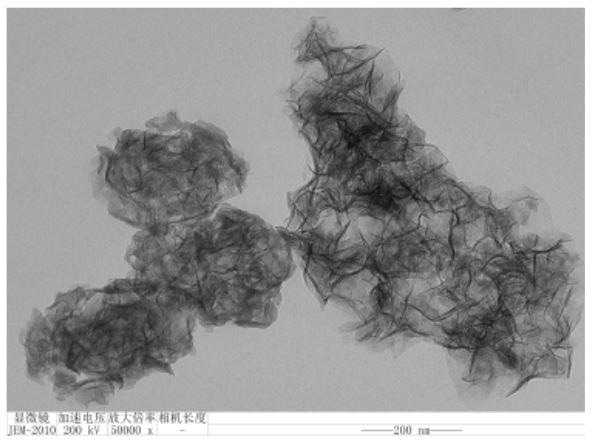

TEM image of flower-like nickel phyllosilicate. Image Credit: Dr. Jinian Yang

The nickel phyllosilicates incorporated into the nanocomposite have a flower-like structure. What aspect of this nanofiller formation aids the efficacy of the EP nanocomposite?

The flower-like morphological structure, as well as the detached nanosheets during the processing and service process, aided the efficacy of the epoxy nanocomposite.

As the friction actions proceed, the flower-like nickel phyllosilicates can be exposed. The nanosheets can then be detached by destroying the flower-like structure of phyllosilicates. These detached nanosheets can be captured, remaining in the contact area between the bulk materials and friction ring, promoting the generation of a strengthened transfer film to improve the tribological properties of EP.

The introduction of excess F-NiPS was shown to negatively affect properties such as tensile strength. Why might this be the case?

We found that this property was closely related to the worsened distribution of the excess F-NiPS.

As the concentration is too high, dispersion decreases, and the tensile strength reinforcement will worsen. Thus, for any polymeric nanocomposites filled with nanoparticles, there shall be an optimum concentration.

EP is widely used in both personal and industrial practices. However, there has been little research into how flower-like nanofillers can improve tribological properties. Do you think that the success of F-NiPS will help generate more interest in this field of study?

This is a potential outcome.

The nanofillers with flower-like structures show some great features when compared to traditional nanofillers.

For example, the flower-like structure provides a very rough surface, which allows strong interface interactions between nanofillers and the resin matrix. Furthermore, such flower-like morphology can also enable easy decoration with other nanomaterials to form multi-functional composite nanomaterials. So, I think the success of F-NiPS will help to generate more interest in this field of research.

Image Credit: PRJ/Shutterstock.com

The popularity of EP means that it is important to have a synthesis technique that can be scaled, cost-efficient, and have a high yield. Do you foresee any challenges that may limit the wide-scale implementation of your methodology? How could they be overcome?

One challenge involves the synthesis of nanomaterials and the blending technology between the nanofiller and epoxy resin. To expand, it was hard to obtain the homogeneously dispersed nanofiller in the polymer resin.

Are there any other nanomaterials, phyllosilicates, or otherwise, that you be interested in investigating?

I would say so. One example is ferric phyllosilicate, which may also help to improve the flame retardant properties of epoxy.

In fact, we can try our best to introduce adequate metal ions into the phyllosilicate, combining the benefits of special metal elements and the lamellar structures of phyllosilicate. Some exciting results might be obtained when employed as the functional nano-reinforcement in polymeric nanocomposites.

What are the next steps for this field of research?

The next steps would involve trying to further decrease the friction coefficient of epoxy nanocomposites.

What aspect of this research do you find personally exciting?

I found the combination of flower-like nanofillers and polymer resin to be the most exciting. In future research plans, we can try to decorate the flower-like nanofillers with different nanomaterials or elements. In doing so, the nanofillers with superior performances shall be unveiled, and the properties of polymeric nanocomposites will be strengthened.

Where can our readers go to see the progression of epoxy resin nanocomposites?

Of course, the web of science, and our most recent research published in Frontiers of Chemical Science and Engineering.

About Dr. Jinian Yang

I obtained a BEng in Materials Science and Engineering followed by a Ph.D. in Materials Processing Engineering from the Nanjing University of Aeronautics and Astronautics. I worked as a teacher and researcher in the Anhui University of Science and Technology, focusing on the synthesis of functional nanomaterials and extending potential applications to polymeric nanocomposites.

Disclaimer: The views expressed here are those of the interviewee and do not necessarily represent the views of AZoM.com Limited (T/A) AZoNetwork, the owner and operator of this website. This disclaimer forms part of the Terms and Conditions of use of this website.