Nanotechnology researchers in Korea recently demonstrated a new additive silicon nanocomposite manufacturing process that could overcome a major challenge in producing so-called metalenses. With applications ranging from biomedical inspection to quantum materials analysis, metalenses could revolutionize nanoscale imaging.

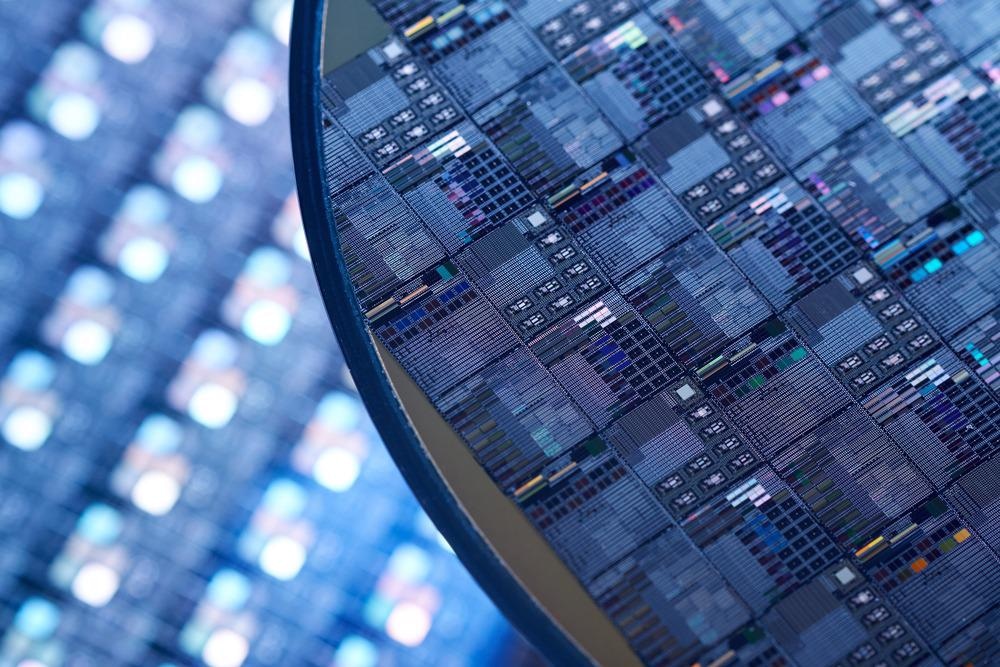

Image Credit: fotografos/Shutterstock.com

What are Metalenses?

Metalenses are thin-film materials whose nanostructures focus light. They are a recent application of advanced quantum physics and can theoretically overcome the diffraction limit of conventional optical microscopy.

Metalenses replace the traditional lozenge shape of optical lenses with an ultra-thin film of silicon dioxide. A pattern of nanoscale trenches is etched into the surface. These trenches are about the same size as the wavelength of light, and they bring photons passing through the thin film into focus.

The tiny nanostructure in the metalens surface focuses the light through a flat material, but it does so using optical – or nano-optical – phenomena. Metalenses could also be flexible or custom shaped depending on the application, making them well suited for applications in wearables and future novel image sensor requirements.

Finally, metalenses can be etched into ordinary silicon chips. This means that they can share production space with other electronic components, resulting in integrated optoelectronic device manufacturing that would create its own benefits.

Entirely new designs of optical components – like optical chips – are on the horizon as this exciting new technology develops.

Metalens Production Challenges

Electron beam lithography – a costly and relatively slow process – has been the preferred manufacturing method for metalenses so far. However, the cost and productivity issues of electron beam lithography have constrained growth in the commercial metalens sector.

To solve this issue, printable materials with a high refractive index are under investigation. This would enable mass production using nanoscale additive manufacturing, but no material had been found that met the requirements for metalenses until recently.

Printing Metalenses

The new paper, published in ACS Nano, characterizes a high-throughput, scalable nanocomposite printing method that offers a low-cost manufacturing solution for metalenses.

Previous research had already identified titanium dioxide (TiO2) and gallium nitride (GaN) as good candidates for high-efficiency metasurfaces., but manufacturing with these materials requires complex and expensive deposition and etching, making them unsuitable for commercial applications.

The authors, based in Pohang University of Science & Technology (POSTECH), Korea, created a printable silicon nanocomposite to overcome these difficulties. The new nanocomposite material can be made into metalenses in just one printing step. The simple process creates a high-efficiency metasurface without requiring any secondary operations like thin film deposition or plasma etching.

The researchers dispersed silicon nanoparticles in a matrix of UV curable resin to synthesize the nanocomposite material, achieving a high refractive index in the material, optimizing the subsequent metalenses’ performance.

Notably, the mold can continue to be used for successive prints, enabling large-scale metalens manufacturing to take place.

Scientists reported a focusing efficiency of 47% at λ = 940 nm with their new metalens, and also said that more efficiency was possible by optimizing the silicon nanocomposite’s composition further.

Using Silicon Nanoparticles

The key element in this nanocomposite was silicon nanoparticles, but researchers pointed to a few other candidates that they intend to test. Among other kinds of nanoparticles, quantum dots and upconverting nanoparticles have come under the team’s scrutiny.

Functional nanoparticles like these can be used in metalens applications, said researchers, but their effects have not yet been fully understood. The team anticipates new quantum nanophotonic phenomena may be discovered if these nanoparticles are explored along with developing novel nanophotonic devices like nanolasers.

The process developed for printing silicon nanocomposites into metalenses also has applications beyond the initial scope of study. The researchers said that their printing process could be applied in advanced technologies like meta holograms, color filters, perfect absorbers, and optical cloaks.

Applications for the New Printable Metalens

The nanocomposite printing technique was used to create near-infrared (NIR) metalens. This type of metalens has applications in LiDAR sensors as receivers, in infrared (IR) cameras, CCTV, night vision devices, and biometric devices for vein recognition.

The method can also create visible light metalenses. This type of metalens has applications in ultrathin optical camera modules for smartphones and future wearables.

Nanoscale image sensors have numerous applications in the future Internet of Things (IoT) and in combination with artificial intelligence (AI) systems, machine learning in industrial processes, and automatic transportation and flight.

Challenges for Metalenses’ Development

This paper joins a growing body of research seeking to optimize and eventually commercialize metalens technology. The authors stress the need for new design principles to continue to correct optical aberrations like spherical aberration, chromatic aberration, and coma.

Researchers said that the laborious and time-consuming nature of numerical simulation needed for research in metasurfaces is the most significant barrier to progress at the moment. Developing new approaches to designing metasurfaces – such as the innovative printing process described in this paper – is necessary for the technologies’ continued advancement.

The team pointed to artificial intelligence (AI) techniques such as deep learning as potential routes for developing new nanostructures.

Continue reading: Nanostructured Thin Films in Gas Sensor Devices: An Overview.

References and Further Reading

Berger, M. (2021) Printable nanocomposite overcomes the manufacturing limitations of metalenses. NanoWerk. [online] Available at: https://www.nanowerk.com/spotlight/spotid=56993.php

G. Yoon et al. (2021) Printable Nanocomposite Metalens for High-Contrast Near-Infrared Imaging. ACS Nano. Available at: https://doi.org/10.1021/acsnano.0c06968.

MIT Technology Review (2019) Why metalenses are about to revolutionize chip-making. [online] Available at: https://www.technologyreview.com/2019/07/09/238863/why-metalenses-are-about-to-revolutionize-chip-making/.

Zou, X., G. Zheng, and S. Human (2020) Imaging based on metalenses. PhotoniX. Available at: https://doi.org/10.1186/s43074-020-00007-9

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.