The atomic force microscope (AFM) is a powerful scientific instrument, but its traditional application as a costly macroscale device prevents it from being used more widely. An on-chip AFM concept can significantly lower the cost and complexities of the AFM, allowing its applications to be widened.

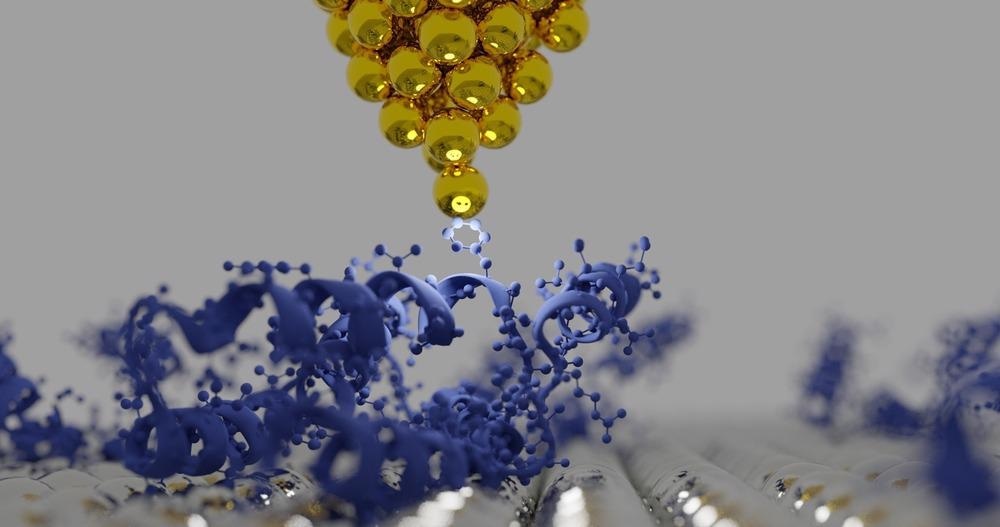

Image Credit: sanjaya viraj bandara/Shutterstock.com

On-chip AFM offers the features of photonic monitoring systems with on-chip miniaturization and sub-nanometer precision. The bending of a detecting cantilever is measured using an incorporated on-chip photonics waveguide while the spacing between the detecting cantilever and interrogation diffraction is monitored.

The technique used achieves the highest adaptive optics sensitivity and accuracy, as well as on-chip miniaturization and array flexibility. This paves the way for a low-cost AFM interpretation solution that doesn't compromise measurement precision, device miniaturization, or the flexibility to function in multi-head setups for quick large-area scanning.

Conventional Atomic Force Microscopy

Atomic force microscopy (AFM) is a form of electron microscopy that has been shown to have resolution on the scale of nanoscale dimension, which is more than 1000 times greater than the visual percolation threshold.

A cantilever with a precise probe tip is at the AFM's core. It is swept across a sample's surface while recording the fluctuating intermolecular interactions that occur between the probing tip and sample.

The data is acquired by using a mechanical probe to "sense" or "contact" the material. Piezoelectric components offer precision scanning by facilitating small yet exact and accurate motions on (electronic) commands.

Limitations of Conventional Atomic Force Microscopy

Macro-scale techniques are used in traditional AFM systems. Due to their substantial acquisition costs, they are out of reach for people and organizations outside of specialist scientific areas. Furthermore, conventional AFM devices need constant optical synchronization and have proven too difficult to commercialize.

Conventional AFMs are often limited to specialized laboratory-based uses due to their size, sophistication, and expense.

Need of Development of On-Chip AFM

Traditional AFMs offer a higher resolution, but their size, convenience of use, and affordability have still not been prioritized; as a result, AFMs have remained confined to specific applications.

Development of on-chip AFM is needed to render nanotechnology more practical, and to enable new applications that demand reliable, low-cost, elevated measurements at the nanoscale size.

Working Methodology of On-Chip AFM

The on-chip AFM is designed to work in tapping mode. Electrostatic transducers are used to move the center stage along the in-plane directions, and electrothermal detectors are used to provide a confined control algorithm of the platform.

At the end of the platform, a silicon microcantilever is incorporated and operated in the out-of-plane direction by an aluminum nitride piezoelectric sensor. This sensor is also utilized to measure the cantilever's deflection utilizing a new high-side charge sensing method, which eliminates the need for a traditional laser and photonic detector.

The gadget was successfully utilized to acquire tapping-mode AFM scans of a specimen in closed-loop, with an acquisition range of up to 8 micrometers.

Benefits of On-Chip AFM

The on-chip AFM has a lot of advantages over the conventional AFMs.

The combination of a readout and a detecting microcantilever allows for device minimization. This eliminates the mechanical noise produced by conventional equipment's photonic leverage output, resulting in a very stiff design.

On-chip AFM might offer a cost-effective AFM output technology without losing measuring precision or increased processing complexity.

Any university or company research facility working on micromachining, nanomaterials, surface science, biotechnology, electrolysis, milling, polishing, and other microfabrication-related topics needs an instrument that can scan surfaces with nanoscale accuracy.

Many of these laboratories already share an AFM or submit their materials to be analyzed by an AFM facility. Everyone can have their on-chip AFM due to reduced cost and ease of operation.

Applications of On-Chip AFM

The thickness of a coated thin layer, the integrity of complex devices, or the dispersion of nanoparticles on a substrate can be measured using on-chip AFMs incorporated into a manufacturing process.

On-chip AFMs' modest size and adaptability offer new applications via hybridization. An AFM may be converted to an electronic probe unit, enabling electrical measurements and scanning to be performed on the same device.

An SEM may be equipped with a single-chip AFM to offer nanometric topography information to supplement SEM data. To provide elevated measurement systems, large arrays of AFMs may be combined. The options are limitless.

Conclusion

On-chip AFMs will revolutionize how we engage with objects at the nanoscale by democratizing a potent nanotechnology instrument. This technology may be utilized as a normal research instrument, but it could also be used to assess material characterization rapidly and accurately.

The on-chip AFM technology can profoundly lower the cost and intricacy of the AFM, allowing it to be used in many practical applications.

Atomic Force Microscopy-based Nanoindentation: An Overview

References and Further Reading

Ruppert, M. G., Fowler, A. G., Maroufi, M., & Moheimani, S. R. (2016). On-chip dynamic mode atomic force microscopy: A silicon-on-insulator MEMS approach. Journal of Microelectromechanical Systems, 26(1), 215-225. https://doi.org/10.1109/JMEMS.2016.2628890

Zawierta, M., Jeffery, R. D., Putrino, G., Silva, K. D., Keating, A., Martyniuk, M., & Faraone, L. (2019). Atomic force microscopy with integrated on-chip interferometric readout. Ultramicroscopy, 205, 75-83. https://doi.org/10.1016/j.ultramic.2019.05.011

Quist, A. P., Chand, A., Ramachandran, S., Daraio, C., Jin, S., & Lal, R. (2007). Atomic force microscopy imaging and electrical recording of lipid bilayers supported over microfabricated silicon chip nanopores: Lab-on-a-chip system for lipid membranes and ion channels. Langmuir, 23(3), 1375-1380. https://doi.org/10.1021/la062187z

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.