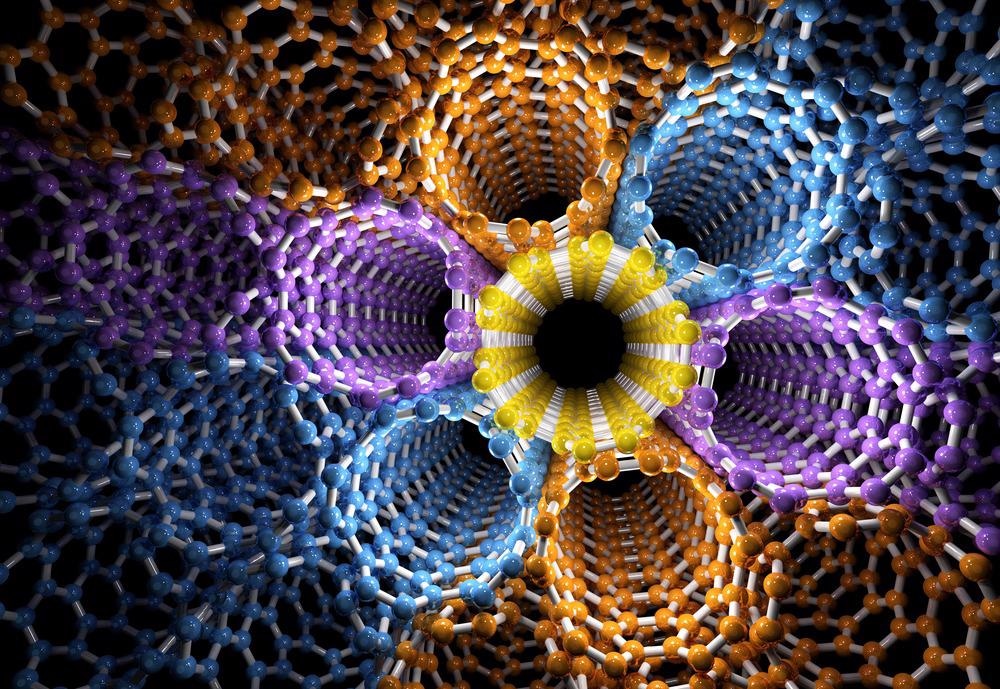

Scientists within the nanotechnology field have significant research interests in carbon nanotubes (CNTs) due to their wide range of applications in sectors like energy, defense, biomedical, automobile, and aerospace. More advanced materials are now obtained through nanomaterials reinforced with carbon nanotubes.

Image Credit: Forance/Shutterstock.com

This article discusses examples of nanomaterials reinforced with CNTs, the effects on the properties of these materials due to reinforcement, and their industrial applications.

Polymer Matrix Composites

CNTs are composed of thin graphite sheets with condensed benzene rings into a seamless tubular hollow cylinder. CNTs are prepared from sp2 hybridized three-dimensional nanotubes and are known to be among the hardest materials on earth.

When CNTs are reinforced with other materials, they enhance their properties in many ways, for example, highly improving strength and toughness.

PMCs or polymer matrix composites are obtained by combining two or more polymer matrices. The unique and exceptional properties of PMCs may not be achieved by individual constituents. However, there are many limitations of PMCs.

These limitations are overcome by combining CNTs with polymer matrices. Nanocomposite scientists have been working with these materials recently due to the advantage of a relatively easy fabrication process without destroying CNT tubular structures.

Several techniques are used for industrial manufacturing of CNT-reinforced polymer nanocomposites, including solution mixing, in situ polymerization, and melt blending. This new class of nanocomposites obtained through these methods are known as CNT-reinforced polymers. Industries prefer these over simple composites due to exceptional thermal, electrical and mechanical properties, high aspect ratio, and low density.

Metal Matrix Nanocomposites (CNT-reinforced MMCs)

MMCs or metal matrix composites are replacing conventional materials in medical equipment, sports goods, defense, aerospace, and automobile industries due to their properties like superior resistance to corrosion and wear, improved electrical conductivity, high modulus, specific modulus stiffness, high specific weight and exceptional strength.

In addition to these characteristics, some particular applications require more advanced composites with superior strength, where there are no-cost constraints for their employment. Then in such circumstances, MMCs reinforced with carbon nanotubes come into play with their technological advancement and improved properties.

Scientists have performed numerous investigations to analyze CNT reinforcements on different matrix materials like Magnesium (Mg), Titania (TiO2), Alumina (Al2O3), Silver (Ag), Steel, Iron (Fe), Titanium (Ti), Nickel (Ni), Copper (Cu), and Aluminium(Al). These different matrix materials are used to prepare CNT-reinforced metal matrix nanocomposites (MMNCs), giving them unique properties. Five examples of such materials reinforced with CNTs are discussed below.

Iron/Steel Reinforced with CNTs

One of the matrices used to prepare CNT-reinforced MMNCs is iron/steel. Salient properties of iron/steel include long lifetime, flexibility, weldability, corrosion resistance, high strength to weight ratio and low maintenance cost. However, reinforcing it with CNT improves or adds several other desirable properties, including improved corrosion resistance and mechanical properties like strength and ductility. The applications of this improved material are in the oil and gas, structural, aerospace, construction and automobile industries.

Al2O3 Reinforced CNTs

Al2O3 matrix is also used for the preparation of CNT-reinforced MMNCs. Some of the noticeable properties of the Al2O3 matrix are good chemical stability, high strength to weight ratio, oxidation resistance, melting point and hardness. The improved properties through this reinforcement are tribological and mechanical properties like fracture toughness. This reinforced material is mainly used in automobile industry, specifically in automobile components.

TiO2 Reinforced with CNTs

Another important matrix used for the preparation of CNT-reinforced MMNCs is TiO2, which possesses good photocatalytic properties, strong bonding and higher mechanical properties.

The reinforced material has improved functional and mechanical properties as well as enhanced tribological behavior. The applications of TiO2 reinforced with CNT material are in several fields, including structural and automobile components, coating materials, electronics and ceramics.

Ti Reinforced with CNTs

The properties of the Ti matrix include high corrosion resistance, excellent formability, low specific gravity, and high melting point. Ti is reinforced with CNTs when improvement is some properties or some new properties are required. These properties may include mechanical properties like hardness and yield strength, low thermal conductivity, creep strength and wear resistance. Ti Reinforced with CNT has applications in automobile, oil and gas drilling equipment, construction, biomedical, medical implantation and aerospace industries.

Mg reinforced with CNTs

Mg matrix reinforced with CNTs has applications in electrical, transportation, aerospace, automotive, and lightweight construction industries. Mg matrix is lightweight with good physical and chemical properties. Mg reinforced with CNT has several improved qualities, including tribological behavior, corrosion resistance, and improved strength and stiffness.

Fabrication

As compared to other nanosized reinforcements, CNTs are more suited to the thermal and mechanical property enhancement of MMCs. The major purpose of research behind the manufacturing of CNT-reinforced MMCs is the fabrication of lightweight, tough, stiff and super-strong components with enhanced electrical, mechanical and thermal properties.

To prepare these advanced MMNCs, several fabrication methods are used. These include powder metallurgy (PM), hot extrusion, friction stir processing (FPS), and melt stirring, also known as stir and squeeze casting. Among these techniques, PM is used more often in industries due to advantages like good bonding between CNTs and matrix, uniform mixing, and low processing temperature.

References and Further Reading

Soni, S. K., Thomas, B., & Kar, V. R. (2020). A comprehensive review on CNTs and CNT-reinforced composites: syntheses, characteristics and applications. Materials Today Communications, 25, 101546. https://doi.org/10.1016/j.mtcomm.2020.101546

Maruyama, T. (2021). Carbon nanotubes. In Handbook of Carbon-Based Nanomaterials (pp. 299-319). Elsevier. https://doi.org/10.1016/B978-0-12-821996-6.00009-9

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.