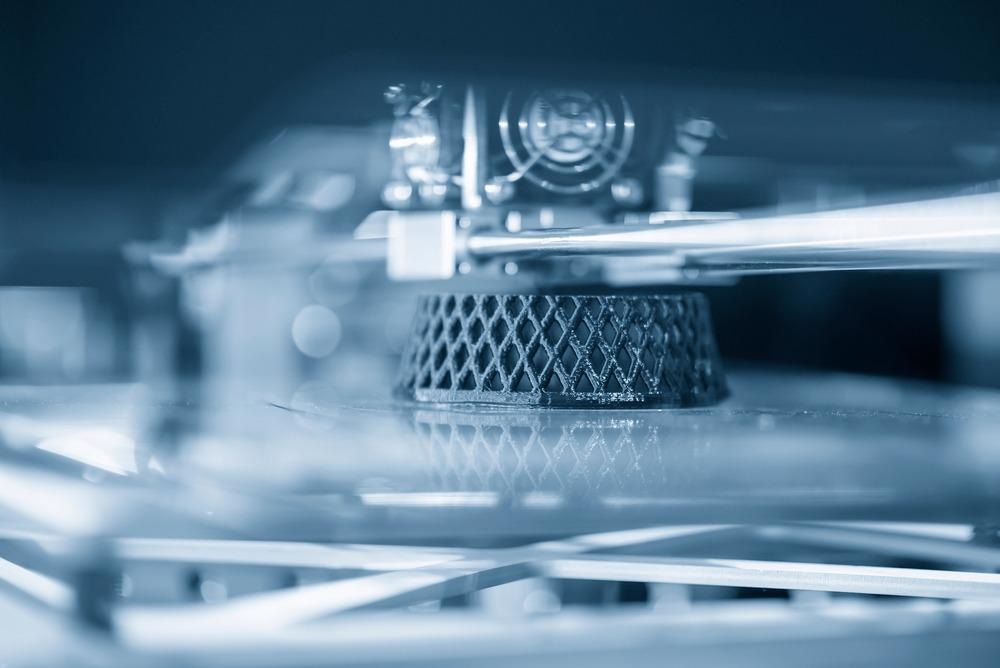

Higher-dimensional precision and faster prototype construction times have been the primary reasons for using 3D printing technology in current enterprises. Because of its capacity to construct complicated interior geometries, 3D printing is a potentially appealing production approach for thermal applications.

Image Credit: Pixel B/Shutterstock.com

This article discusses the significance, advantages, and challenges of 3D printing techniques as well as the importance of nanofillers for enhancing the thermal properties of 3D printed products.

3D Printing: Overview and Potential Advantages

The method of creating three-dimensional solid items from a digital file is known as 3D printing or additive manufacturing. An item is built in an additive technique by putting down consecutive layers of material. Each of these levels is a finely cut cross-section of the structure. 3D printing is the inverse of subtractive manufacturing, which involves cutting or hollowing out a piece of metal or plastic using a milling machine.

This manufacturing technique has many benefits over other conventional manufacturing processes. High flexibility, rapid manufacturing, print on demand, sturdy and lightweight components, quick design, waste minimization, cost-effectiveness, easy accessibility, and eco-friendliness are a few of its remarkable properties.

Traditional methods depend on molds and cutting procedures, making customization time-consuming. In contrast, 3D printing-created objects may have their structural integrity improved, sophisticated alterations done, and pieces adjusted to meet specific needs. Customization in this manner opens up a plethora of industrial uses for 3D printing.

3D Printing for Manufacturing Thermally Conductive Products

Recent improvements in multi-material 3D printing provide the opportunity to extend product design beyond difficult geometries. Single-step manufacturing procedures may be used by leveraging unique composite materials appropriate for multidimensional applications. The fused filament fabrication (FFF) technology is low-cost and offers a diverse selection of feedstock materials suited for various 3D printing applications.

Different polymers, such as polylactic acid (PLA) and polyamide (PA), can be disintegrated and pressed as a strand through a nozzle in FFF. The filament (thermoplastic strands) rapidly reinforces and adheres to the outer layers, beneficial for complex design and innovative features of thermally conductive products.

To create a printable filament with better functionality for FFF technology, the filler component must also be changed to meet the permeability limitations set by 3D printing technology. An upper limit in terms of additive quantity must be considered in this context based on application demands, filler shape and texture, and matrix material qualities.

3D Printed Thermally Conductive Products: Important Challenges

Composite 3D printed composites with thermally conductive qualities have been researched for high-performance aerospace and automobile industries, with decreased manufacturing size and cost, as well as simplicity of fabrication in mind. The effect of filler content on thermal conductivity is considerable, implying that a more thermally conductive filler results in superior thermal conductivity.

Thermal energy is transferred in 3D printed objects by phonon transfer rather than vibration as in pure crystal structures. However, vibrational frequency incompatibilities at impurities and lattice defect contacts produce considerable phonon "scattering" in 3D printed polymers, resulting in poor thermal conductivities.

Use of Nanofillers to Enhance Thermal Properties of 3D Printed Products

Due to their elasticity, ease of processing, lightness, cheap cost, excellent chemical stability, and mechanical qualities, polymers such as polylactic acid (PLA), ABS, polypropylene (PP), polyethylene (PE), and polyetherimide (PE) have been extensively employed in industry for decades. The only technical impediment to these polymers is their low thermal conductivity.

Integrating highly thermally conductive nanofillers in the host polymer by forming heat transfer pathways is a cost-effective approach to improve its thermal management application areas, such as heat sinks and other elements for electric devices.

Nanofillers for 3D Printing Thermally Conductive Products: Recent Examples

Thermoplastic PA12 offers a wide variety of uses in the electronics industry, including cable wrapping and insulating material. Zhang et al modified the thermoplastic PA12 with various nanofillers, including carbon nanotubes (CNTs) and carbon fibers (CFs), and the fillers and composite were assessed for improved structure and thermal conductivity.

Based on the findings, parameter settings were developed to achieve high strands homogeneity and recrystallization for the nanocomposite filaments, therefore removing the majority of structural flaws.

Hu et al investigated a variety of nanofillers, including silver, copper, halloysite, and other nano clays. These fillers were mixed into a photopolymer resin, cured, and tested for thermal conductivity, tensile characteristics, contact angle, and toughness.

The findings showed that including conductive copper and silver nanoparticles did not influence the thermal properties of the resin.

The introduction of Halloysite nanoclay loading at three wt percent, on the other hand, dramatically boosted the thermal conductivity of the resin. These findings suggest that nanofiller may be utilized to improve the heat conductivity of commercially accessible 3D printed items. However, further research is required before these materials can be considered a viable alternative to standard production procedures.

References and Further Reading

Halim, N. A. et al. (2021). A review on 3D printed polymer-based composite. IOP Conf. Series: Materials Science and Engineering. Available at: https://doi.org/10.1088/1757-899X/1078/1/012029

Hu et al. (2019). Nanofillers can be used to enhance the thermal conductivity of commercially available SLA resins. Procedia Manufacturing, 38, 1236-1243. Available at: https://doi.org/10.1016/j.promfg.2020.01.215

Koumoulos, E. P. et al. (2017). Additive (nano)manufacturing perspectives: the use of nanofillers and tailored materials. Manufacturing Rev. Available at: https://doi.org/10.1051/mfreview/2017012

Zhang, Z. et al. (2022). 3D Printing Processability of a Thermally Conductive Compound Based on Carbon Nanofiller-Modified Thermoplastic Polyamide 12. Polymers. Available at: https://doi.org/10.3390/polym14030470

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.