Sponsored by Genizer LLCReviewed by Louis CastelJul 12 2022

Homogenization is the name given to any of the processes used to make a mixture of two mutually non-soluble liquids the same throughout. To achieve this, one of the liquids is altered to a state wherein the minute particles are uniformly distributed across the other liquid. In other words, homogenization is the act of combining two immiscible liquids into an emulsion.

In high shear homogenizers, Genizer homogenization technology uses a microfluidic Diamond Interaction Chamber (DIXC) to create homogeneous nanoparticles.

To provide a consistent processing profile, the processed fluid moves through the fixed geometry inside the Y-type and Z-type microfluidics chamber (which is also known as a continuous microreactor). Oil-in-water and water-in-oil nanoemulsions (100–1000 nm) can be created using this technique.

High-Pressure Nozzle, Impact Valve, or Microfluidics Chamber (Microreactor)?

Irrespective of the flow rate, high-pressure homogenization process pumps can deliver 100–300 MPa hydrostatic pressure to a liquid without imposing any flow restrictions. The current industrial, pilot and lab-scale high-pressure homogenizers use plunger-like pumps and valves, nozzles, or chambers composed of strong ceramics or precious stones that are resistant to abrasion.

Effective homogenization is characterized by cavitation (Figure A), impact (Figure B) and shear. One or more of these qualities are supported by the valves, nozzles, or chambers.

Table 1. Selection Guide for Chamber Types. Source: Genizer LLC

| . |

| Type of Chamber |

Cavitation Nozzle (Figure A) |

Impact Valve (Figure B) |

Y-Type Chamber (Figure C) |

| Application |

High viscosity liquid, suspension or paste |

Food, Beverage |

Pharmaceutical Emulsion,Nanoparticles |

| Advantage |

Old Style |

Use for Food |

High Efficacy |

Three-Types Homogenizing Mechanism in History. Image Credit: Genizer LLC

Manufacturers for high pressure homogenizer like Genizer, Microfluidics (Y-type interaction chamber), Avestin (static homogenizing valve) and Nanomizer (collision-type generator) have all employed the Y-type interaction chamber (Figure C), which is regarded as one of the most powerful chambers to date.

In these systems, the flow stream is divided into two channels, which are then driven into a single flow stream by being directed at right angles across the same plane. The high pressure generates a high speed at the crossover of the two flows, resulting in turbulence, cavitation and high shear, over the single outbound flow stream.

A very small hole (nozzle) of 50~400 μm in diameter is typically found between two blocks of diamond or ceramic that make up the Y-type chamber. First, two block-forming parts are flattened visually by being ground and lapped.

Then, precisely aligned grooves are fixed into each block’s face in the correct sizes and shapes. Homogenization energy is concentrated where the liquid streams collide in the internal drain at the collision point.

Y-type chamber made by two blocks of an optically flat disk. Image Credit: Genizer LLC

Y-Type Diamond Interaction Chamber (DIXC) is used to produce uniform nanoparticles in a high pressure homogenizer. The fixed geometry within the Y-Type DIXC is intended to create a uniform processing profile so that all materials will be processed with equal disruptive forces. Single-slotted interaction chambers have a single microchannel and are ideal choices for small batch research, while the multi-slotted interaction chamber comprises multiple microchannels in parallel, which can be used at industrial scales, by increasing the flow rate through the DIXC but with equal processing forces.

Structure of Y-type chamber and Y-type-RT chamber. Image Credit: Genizer LLC

Photo of Y-type chambers and Y-type-RT chambers. Image Credit: Genizer LLC

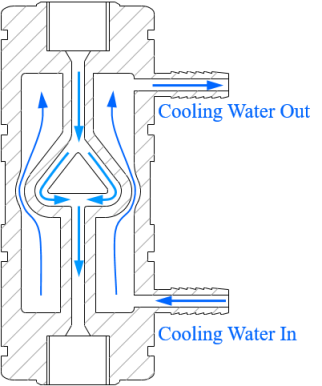

NanoGenizer high pressure homogenizer is composed of a feed reservoir, high pressure pump, transducer, PLC control panel and microfluidics diamond interaction chamber. The sanitary pump system of the NanoGenizer high pressure homogenizer is able to supply the desired pressure to the product stream and push it through the Y-type or Z-type chamber to create high shear rates and strong impact within the stream. Application of NanoGenizer High Pressure Homogenizer includes: Cell disruption; particle size reduction; Nano emulsions; Nano dispersions; Liposomes; Deagglomeration; Vaccine production and so on.

Nanogenizer high pressure homogenizer equipped with Y-type chamber. Image Credit: Genizer LLC

Table 2. Pressure and chamber selection for various applications with NanoGenizer. Source: Genizer LLC

| . |

| Cells |

Mammalian cell |

Insect cell |

Bacteria cell |

Yeast cell |

Algae cell |

SPore |

| |

|

|

|

|

|

|

| Sample |

CHO | Hela |

Sf9 | Sf21 | H5 |

E. Coli |

Yeast |

Green algaea |

Ganoderma |

| Pressure |

600-800 bar

8500-11500 psi |

600-1000 bar

8500-14500 psi |

800-1000 bar

11500-14500 psi |

1200-1400 bar

17500-20000 psi |

1200-1500 bar

7500-21500 psi |

1300-1600 bar

18500-23000 psi |

| Chamber |

F20Y, F20Y-RT |

F20Y, F20Y-RT |

F20Y, F20Y-RT |

F20Y, F12Y |

F20Y, F12Y |

F20Y, F12Y |

| . |

| Emulsions |

Oil in water emulsions |

Water in oil emulsions |

Oil emulsion |

Food |

Liposome (o/w) |

Liposome (w/o) |

| |

|

|

|

|

|

|

| Sample |

Fat emulsion | Prostaglandin |

Cosmetics |

Dimethicone | Fuel |

Milk |

Doxorubicin |

DNA | lipopolyplex |

| Pressure |

~20,000 psi |

~10,000 psi |

~20,000 psi |

~10,000 psi |

~20,000 psi |

~8,000 psi |

| Chamber |

F20Y, F12Y |

F20Y |

F20Y, F12Y |

F20Y |

F20Y, F12Y |

F20Y |

| . |

| Dispersions |

Pigments |

Drugs/Creams |

Battery |

Particle aggregation |

Graphene |

Nanotubes |

| |

|

|

|

|

|

|

| Sample |

Inks, Coatings |

Norfloxacin, Isoxyl |

Lithium/ Solar cell |

Nano fibril |

Graphene |

Carbon Nanotubes |

| Pressure |

~20,000 psi |

~20,000 psi |

~20,000 psi |

~25,000 psi |

~50,000 psi (single layer) |

>20,000 psi |

| Chamber |

F20Y, F12Y |

F20Y, F12Y |

F20Y, F12Y |

F20Y, F12Y |

F20Y, F12Y |

F20Y, F12Y |

This information has been sourced, reviewed and adapted from materials provided by Genizer LLC.

For more information on this source, please visit Genizer LLC.