Nanopositioning is the name behind the technology of moving, measuring, and positioning a device or instrument to sub-micron levels of accuracy – this means movement over extremely small distances, often at high speeds.

Nanopositioning systems are designed to produce repeatable, high-precision movements in increments of one nanometer or less over a distance of a few microns. Devices that travel 1.0 mm are considered to be operating at the extremes of nanopositioning technologies.

A nanopositioning system is typically used to move and position devices such as sensors, probes, or scanners. Nanopositioning systems need to move the device to a set position and hold it precisely in place for extended periods or position, hold and reposition the device multiple times at high speeds.

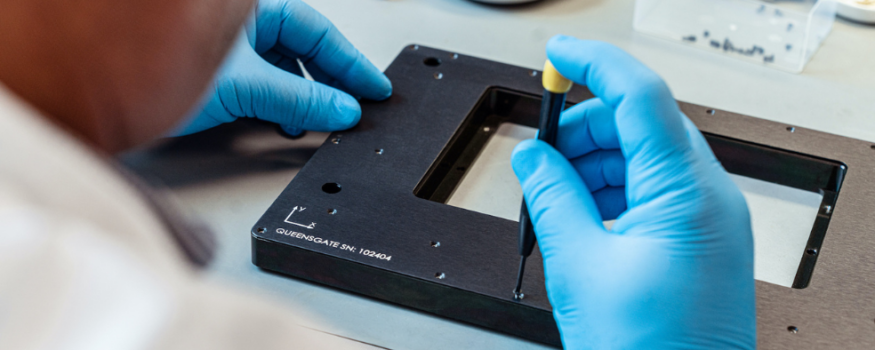

Image Credit: Prior Scientific

Where are Nanopositioning Systems Used?

Nanopositioning systems are able to move rapidly and consistently maintain nanometer levels of accuracy, making them ideal for a wide range of precision applications in research and industry.

Applications include high-performance linear stages used in the production of read/write heads in computer hard drives, medical devices such as laser mirror positioning in eye surgery, live cell imaging, multi-photon microscopes used in neuroscience, and DNA sequencing.

Nanopositioning systems are also used in materials research, where they are applied in atomic force microscopy.

How does a Nanopositioning System Work?

Nanopositioning systems can be constructed in a number of ways, with the most effective based on proven piezoelectric technology. Queensgate, a brand of Prior Scientific, pioneered this technology.

The piezoelectric effect was originally discovered in 1880 by Jacques and Pierre Curie. When a mechanical force is applied to quartz or other crystals, it generates an electric charge within the crystal.

The original discoverers of the piezoelectric effect showed that an electrical field also causes the crystal to expand or contract; this subsequently became known as the inverse piezoelectric effect.

Nanopositioning systems exploit this phenomenon, using an electric signal to energize a stack of piezoelectric layers that expand in response to an applied voltage.

By fixing one side of the mechanism to a reference base plate, also termed a stage, while allowing the other to move, a linear actuator capable of sub-atomic resolution with extremely high mechanical stiffness can be produced.

For instance, a piezoelectric stack that is 20 mm in length can be comprised of two hundred layers, each one hundred microns thick.

The stack would expand by fifteen microns for every one hundred applied volts. This can generate a force of around 750 N. The inherently high degree of stiffness results in correspondingly high resonant frequencies, enabling devices to move rapidly in a controlled manner.

Piezoelectric devices are non-linear and exhibit hysteresis, however. These devices, therefore, require an external sensor to control their precise position.

Capacitance sensors are typically employed, which comprise two thin conducting films approximately five hundred microns apart, separated by a dielectric air gap to give a set capacitance value.

Movement can be detected as a capacitance change by attaching one side of the sensor to the moving stage of the nanopositioning device and the other to the fixed stage.

Using this measurement as input to a feedback control loop enables the exact position of the moving stage to be determined with outstanding resolution, linearity, stability, and repeatability.

Specially machined flexures complete the system. These are designed to guide each axis of motion, together with mechanical amplifiers and sensing and control electronics, creating a device that can make pure orthogonal motions with sub-nanometer levels of precision.

Queensgate: The Nanopositioning Experts

Queensgate has been designing, developing, and manufacturing advanced nanopositioning systems for almost five decades. The company operates at the forefront of research into the science of sub-atomic movement, measurement, and positioning.

Queensgate has pioneered and perfected the application of piezoelectric and capacitance sensing technologies. The company’s systems are used around the world in sectors ranging from scientific and medical research to electronics and other industries.

Queensgate is positioned as an industry leader and go-to expert in nanopositioning, with unrivaled knowledge and experience. Contact the experts to learn more about nanopositioning and the company’s range of solutions.

This information has been sourced, reviewed and adapted from materials provided by Prior Scientific Instruments Ltd.

For more information on this source, please visit Prior Scientific Instruments Ltd.