In this interview, we speak with John Kulikowski from Stanford University's Gu Group about his involvement in research that reports the development of a new metal nanocluster-based material that could help advance nanoscale 3D printing.

Please could you introduce yourself and tell us about your current position and research activities?

I am John Kulikowski, a 4th year Ph.D. candidate in Mechanical Engineering at Stanford University School of Engineering working in Professor Wendy Gu’s research group. My work focuses on projects using two-photon lithography, including studies on how shape affects self-assembly of microparticles and the mechanics of micro/nano-lattices. Additionally, I study novel composite materials for two-photon lithography.

How did you become involved with this investigation in particular?

Our group has previously worked with these ultrasmall nanoclusters and has been working on other projects using two-photon lithography.

Once the nanoclusters were identified as suitable candidates for two-photon absorption, it became clear that we could produce a working photoresist with the clusters. From there, it made sense to study the photoresist’s mechanical properties because we knew that the nanocluster would act as mechanical reinforcements.

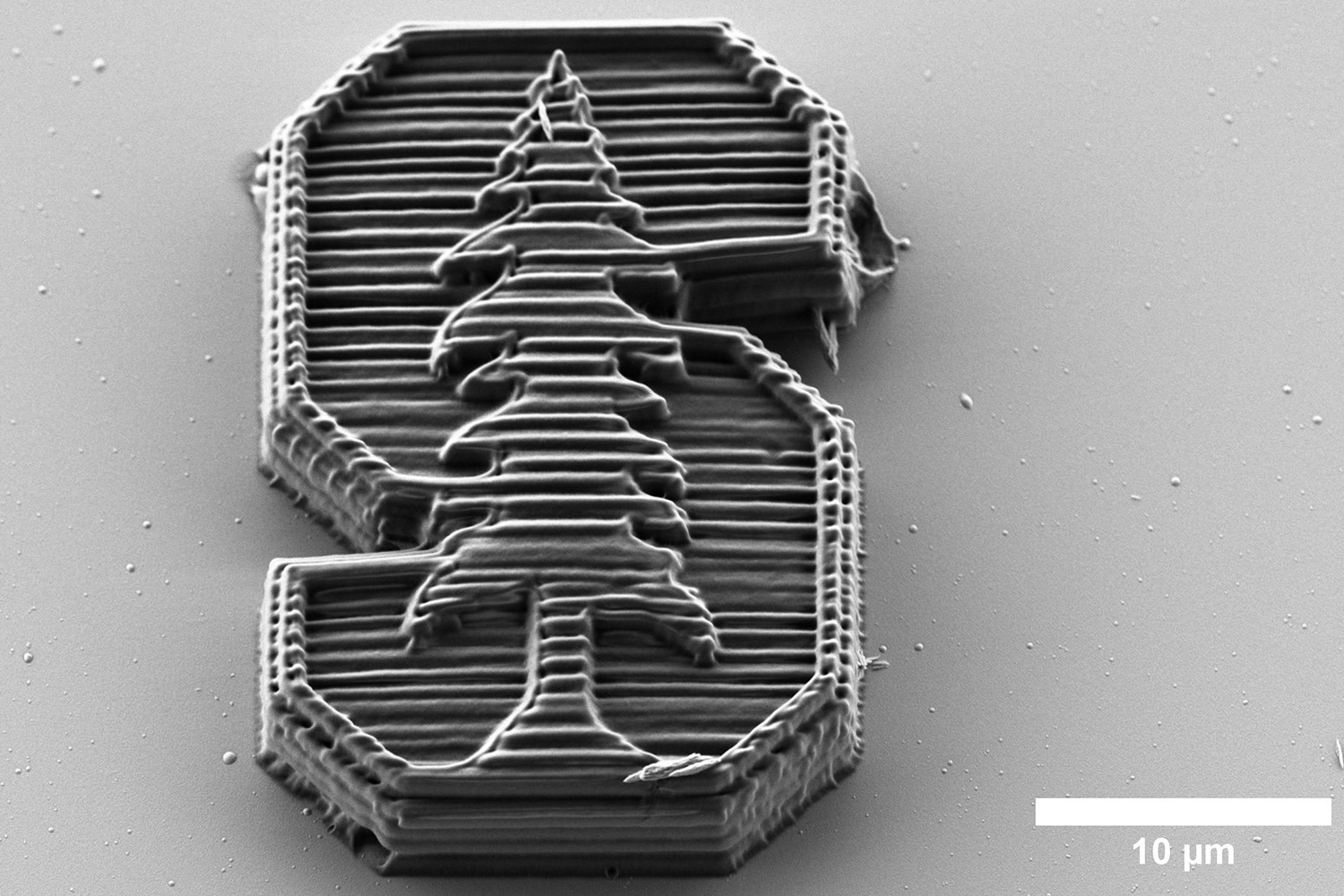

Tiny but strong Stanford logo made using nanoscale 3D printing. (Image credit: John Kulikowski)

Why is there so much interest in 3D printing, especially in approaches that can 3D print at small scales?

3D printing enables us to customize parts and create any part or geometry needed. Small scales would enable us to create these parts for microscale applications such as microelectronics. Further, microscale printing allows us to design entirely from the bottom up and better mimic the complexity of materials found in nature.

Could you discuss the newly developed material for nanoscale 3D printing and its key characteristics?

Our newly developed material makes use of metal nanoclusters. These metal nanoclusters are atomically precise particles ~1-2nm in size. They interact with light in a way that enables the two-photon light absorption (which allows for high-precision printing) more efficiently than the typical organic molecules used to initiate this process.

Further, these particles improve the mechanical performance of the material as a mechanical reinforcement. This gives rise to impact-resistant and recoverable material that can be printed in arbitrary shapes.

We show that the inclusion of nanoclusters is a versatile printing method for multiple materials (such as silk), and that the nanoclusters can create a porous material through a time-temperature heating process.

What specific benefits does the inclusion of metal nanoclusters offer, and would you consider using a different material in the same way in the future?

The inclusion of metal nanoclusters aids in the two-photon lithography process and acts as a stiff mechanical reinforcement in the polymer matrix.

Indeed, other particles or molecules can act as photo-initiators for two-photon lithography. However, most of them do not also act to mechanically reinforce the polymer. Additionally, other particles can be used as mechanical reinforcement but generally do not take part in the lithography process.

Other types of metal nanoclusters could potentially act similarly to the two we studied in our work; combinations of photo-initiating molecules and stiff filler particles could achieve similar materials.

Did you encounter any challenges in developing this material? How did the team approach this?

There were plenty of challenges in developing this material. Primarily, dealing with the solubility and purity of the metal nanoclusters in the polymer monomer base was challenging and required many iterations to develop a stable photoresist. Lots of feedback, collaboration on the printability and longevity of the photoresists, and minor adjustments to resist chemistry were required for success.

Satellites, drones and microelectronics are some applications that could benefit from this research. Are there any other industrial sectors that would find this material advantageous?

Additionally, this material could be used for biomaterials such as micro-swimmers by creating parts with variable stiffness. This research could also be useful in micro-robotics to make more robust components.

This material is likened to bio-inspired structures such as bone. Why is it beneficial to consider the natural world when developing innovative new materials?

The natural world is full of complexities that have already solved many problems which we currently face. In this case, a strong, lightweight material. It is logical to take inspiration from naturally occurring materials to inform our structural designs.

What are the next steps for this research?

We are continuing to focus on improvements in the material but changing the nanocluster concentration, types of nanoclusters and through heat treatment.

We may be able to further improve the properties of this novel material class through these methods. Further, the 3D printing technique allows us to produce arbitrary geometries, giving us an infinite space to explore structural design.

We can further iterate on impact resistance structures or branch out to a variety of applications, such as thermal management or catalytic materials.

About John Kulikowski

John Kulikowski is a 4th year Ph.D. candidate in Mechanical Engineering at Stanford University School of Engineering. In his first three years at Stanford, John was awarded a Stanford Graduate Fellowship as the PACCAR Inc. Fellow. He currently serves as the Gu Lab’s safety officer and as a course assistant for the undergraduate dynamics course in the School of Engineering.

John Kulikowski is a 4th year Ph.D. candidate in Mechanical Engineering at Stanford University School of Engineering. In his first three years at Stanford, John was awarded a Stanford Graduate Fellowship as the PACCAR Inc. Fellow. He currently serves as the Gu Lab’s safety officer and as a course assistant for the undergraduate dynamics course in the School of Engineering.

John’s current research focus is on mechanical metamaterials made via two-photon lithography (2PL). His current studies in 2PL focus on two primary areas: the production of novel nano-composite materials and self-assembly of microparticles made via 2PL.

Novel composite materials give rise to advanced architected materials with superior and otherwise unattainable mechanical, acoustical, and/or optical properties. John hopes to better understand the interdependence of material selection and geometrical design. Self-assembly studies focus on the driving forces and shape-dependence of assembly with the potential to create a bottom up, scalable techniques to produce novel materials.

Disclaimer: The views expressed here are those of the interviewee and do not necessarily represent the views of AZoM.com Limited (T/A) AZoNetwork, the owner and operator of this website. This disclaimer forms part of the Terms and Conditions of use of this website.