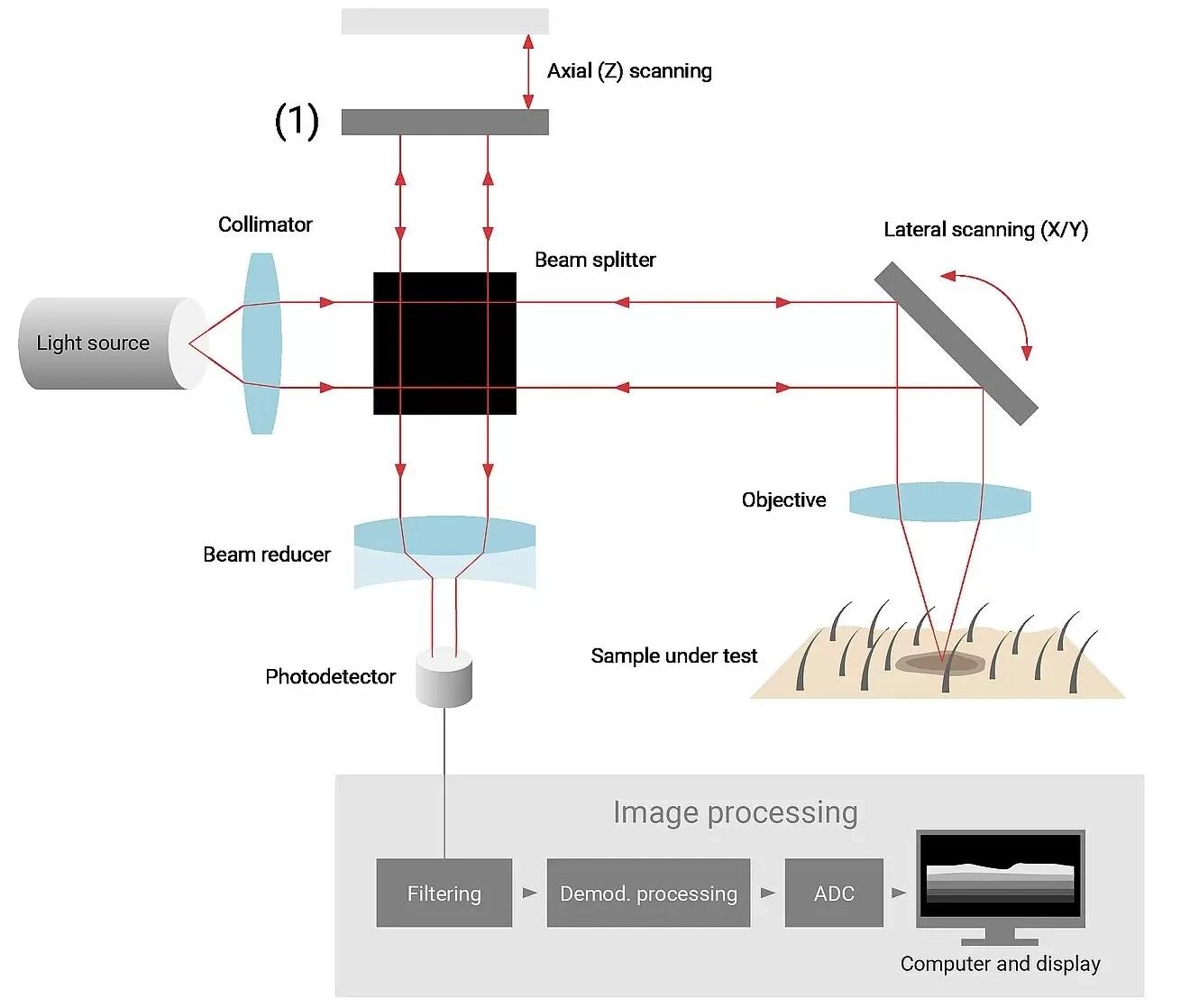

OCT, an interferometric imaging method, relies on wide-spectrum infrared light (usually from 0.8 µm to 1.4 µm) for optimal tissue penetration.

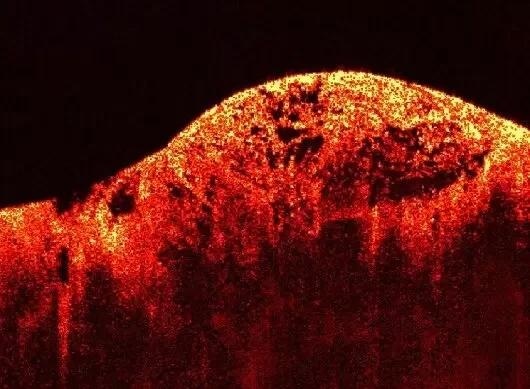

Traditionally used in ophthalmology, OCT has now expanded its utility in dermatology, aiding in skin cancer treatment. Compared to conventional invasive diagnostic methods, OCT yields quicker results, reducing patient stress and side effects.

Basic principle of an Optical Coherence Tomography / interferometer setup. Image Credit: PI (Physik Instrumente) LP

Image of a muscle tumor taken with an imaging system based on Optical Coherence Tomography (OCT). Image Credit: Dr. Stephen Boppart, Biophotonics Imaging Laboratory, University of Illinois at Urbana-Champaign / Wikipedia

Precision Motion Systems for Scanning

As OCT relies on axially scanning an optical beam in one interferometer arm, highly accurate nanopositioning stages are essential to achieve maximum imaging resolution. Various drive concepts can fulfill the requirements of modern OCT systems.

- Piezoelectric Flexure-Guided Nanopositioning Scanners

Multiple piezo-driven motion principles are viable. The two examples below utilize piezoelectric stack actuators to drive a flexure-guided stage platform and a microscope objective mount, respectively.

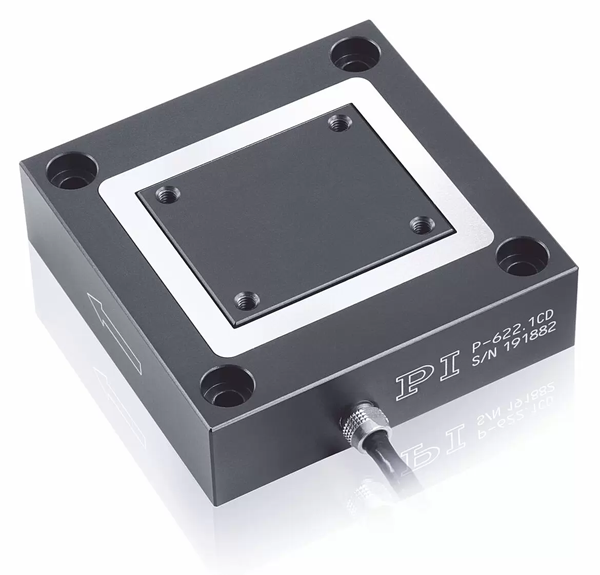

Flexure-guided, piezoelectric linear nanopositioning stages offer the highest resolution and precision—they are also wear-free, friction-free, and require minimal power to maintain a position.

The flexure-guided P-725 piezoelectric scanning and focusing stage is designed to directly integrate a microscope lens. It provides up to 0.8 mm travel, nanometer precision, and very smooth motion. Image Credit: PI (Physik Instrumente) LP

The P-620 to P-629 piezo flexure nanopositioning stage family is based on a similar flexure guidance design as the P-725 and provides travel up to 1.8 mm. Capacitive feedback is integrated for nanometer-precise, closed-loop position control. Image Credit: PI (Physik Instrumente) LP

- Voice Coil Linear Motor-Driven Scanning Stages

Voice coil motors, based on the well-known electromagnetic principle from loudspeakers, are well-suited for motion ranges of approximately 0.5 mm to 25 mm (1 inch). These motors are frictionless, wear-free, and can deliver dynamic and precise motion.

When used in scanning and positioning stages, these are often combined with crossed-roller rails for high-precision guidance.

Linear encoders essential to the scanning stages provide feedback to a closed-loop motion controller, enabling precise position and velocity control.

The V-308 compact fast nano-focusing stage employs a voice-coil linear motor and high resolution optical encoder. Image Credit: PI (Physik Instrumente) LP

The V-528 voice-coil scanner provides 20 mm travel, scanning frequency of 10 Hz, and velocity of 250 mm/sec. Image Credit: PI (Physik Instrumente) LP

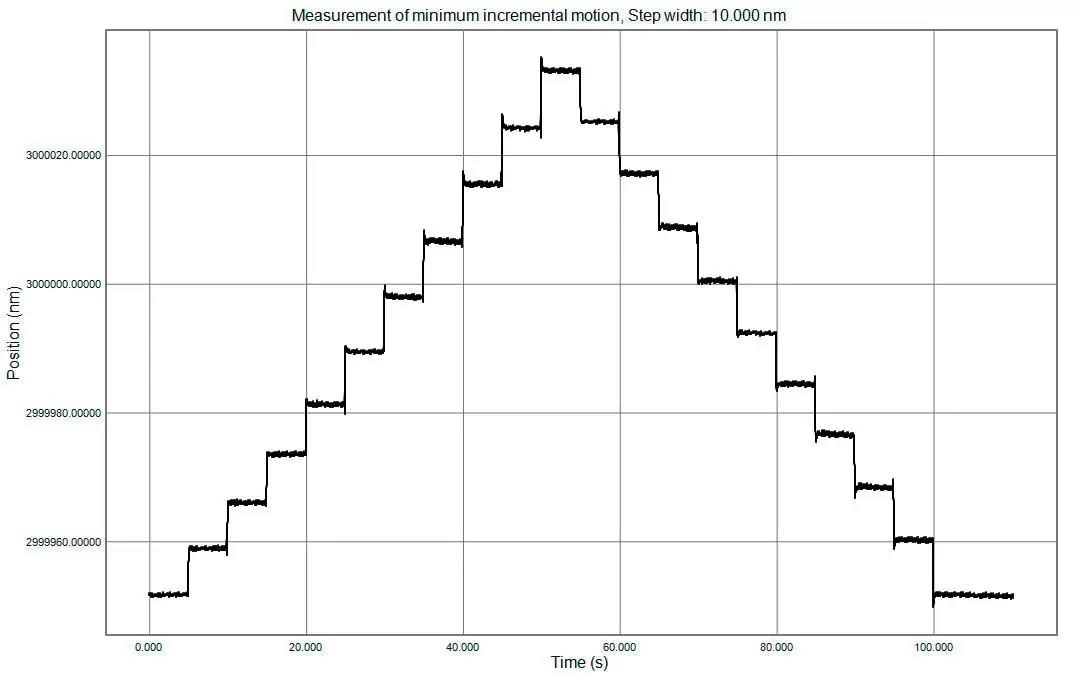

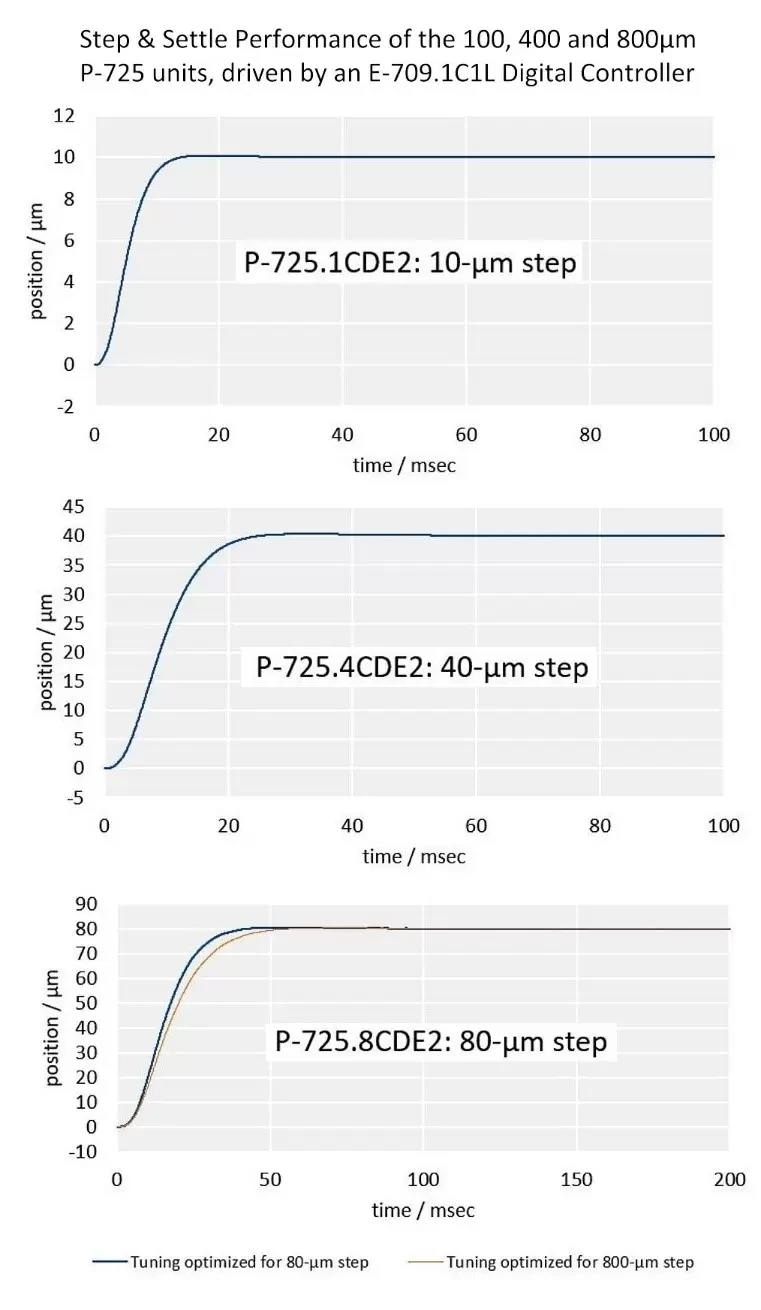

The graphs below depict the settling performance of different piezo-driven objective scanners (right) and nanometer-precise steps of a voice-coil motor-driven scanning stage.

Sequence of 10 nm steps, performed by the V-308 voice-coil scanner. An internal optical linear sensor with sub-nanometer sensitivity provides feedback to a closed-loop motion controller. The total travel range is 7 mm and can be limited by user-adjustable hard stops. Image Credit: PI (Physik Instrumente) LP

Step and settle performance (10 % travel range, 1 % settling precision, with 150 g objective mounted) of the three different P-725 piezo objective Z-focusing drives. Image Credit: PI (Physik Instrumente) LP

Next Generation: Closed-Loop Fast Focusing Nanopositioning Drives: Voice-Coil or Piezo - Your Choice

Next Generation: Closed-Loop Fast Focusing Nanopositioning Drives: Voice-Coil or Piezo - Your Choice. Piezo Scanners and Voice Coil Scanners for Imaging, Metrology, and OCT applications. Video Credit: PI (Physik Instrumente) LP

- Piezo-Motor Driven Scanning and Positioning Stages

Piezoelectric motion/positioning stages, based on the ultrasonic-drive principle, are also accessible. These stages offer travel ranges usually between 10 to 150 millimeters and can be designed to fit into confined spaces.

This U-521 miniature linear stage uses an ultrasonic piezo linear motor and provides 18 mm travel with 0.1 µm encoder resolution. Image Credit: PI (Physik Instrumente) LP

The U-523 linear translation stage is a larger version of the U-521, with 22 mm travel and 10 nm encoder resolution. Image Credit: PI (Physik Instrumente) LP

Linear Stage, XY-Stage, Motorized for Active Photonics Alignment & Scanning: Miniaturized Systems.

Linear Stage, XY-Stage, Motorized for Active Photonics Alignment & Scanning: Miniaturized Systems. A fast XY-scanning table based on ultrasonic motors in a laser scanning / photonics alignment application. Video Credit: PI (Physik Instrumente) LP

XY Linear Stage, Voice Coil Linear Motor for Scanning, Fast, Precision, V-528 Multi-Axis, XY-Table

XY Linear Stage, Voice Coil Linear Motor for Scanning, Fast, Precision, V-528 Multi-Axis, XY-Table. XY-Table. XY voice coil scanning stage. Video Credit: PI (Physik Instrumente) LP

This information has been sourced, reviewed, and adapted from materials provided by PI (Physik Instrumente) LP.

For more information on this source, please visit PI (Physik Instrumente) LP.