X-ray photoelectron spectroscopy (XPS) is widely used for characterizing the uppermost 10 nm of a materials surface. Also called electron spectroscopy for chemical analysis (ESCA), the analytical technique measures photoelectrons ejected from a material under irradiation by monochromated Al Kα X-rays. The technique provides quantitative elemental and chemical state information from the materials surface.

It is utilized in both academic and industrial research, to characterise samples with many technological applications ranging from superhard, inorganic coatings through to organic light-emitting diodes.

The AXIS Supra+ - Improved Performance

The AXIS Supra+ photoelectron spectrometer from Kratos Analytical provides better performance when compared to its predecessor. By combining market-leading imaging and spectroscopic capabilities with automation, the AXIS Supra+ guarantees ease of use and high sample throughput. Unprecedented large-area spectroscopic performance makes it possible to acquire photoelectron spectra with speed and accuracy. Rapid XPS imaging with high spatial resolution shows the lateral distribution of surface chemistry and helps in extra characterization with small area analysis.

Through the ESCApe integrated acquisition and processing software, the AXIS Supra+ performs to its highest capability and offers a convenient interface with the spectrometer.

The AXIS Supra+ provides the highest level of automation. During analysis, the transfer and exchange of the unattended sample holder can be realized through the coordination of the sample analysis chamber auto-stage and the Flexi-lock sample magazine.

Capabilities of the AXIS Supra+ : Large-Area, High-Sensitivity XPS

The AXIS Supra+ offered by Kratos Analytical has been enhanced for chemical state XPS. High transmission electron optics along with an efficient collection of photoelectrons guarantees unparalleled resolution and sensitivity at large analysis areas. Besides the standard scanned acquisition, spectra can be acquired in rapid, unscanned snapshot mode within a second through the 128-channel Delay-Line Detector (DLD).

Following are the main attributes:

- Data can be obtained rapidly

- Light elements can be easily identified

- Exceptional signal-to-noise ratio, even at reduced concentrations

- Includes scanned or snapshot spectral acquisition modes

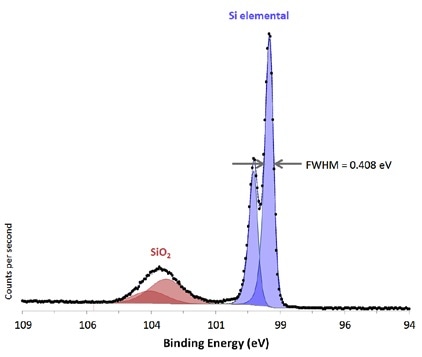

High-Energy Resolution

The best possible energy resolution is the central requirement of any spectrometer. Kratos Analytical’s AXIS Supra+ has a large 500-mm Rowland circle monochromated Al Kα X-ray source and improved electron optics, which ensure remarkable chemical resolution.

Following are the benefits offered by the high spectral energy resolution:

- Assured energy resolution on both conducting and insulating samples

- Accurate identification of chemical shifts

Si 2p region from native oxide on Si substrate acquired from large area with high-energy resolution.

Small Spot, Selected Area Spectroscopy

Better performance of the AXIS Supra+ small spot ensures high sensitivity in small spot mode. This is realized by improving the sample’s X-ray illumination with the chosen analysis area. An optional brite-X monochromatic source can also be designated for applications in which extremely high sensitivity performance is expected from small chosen areas.

Main attributes of the selected area spectroscopy are listed below:

- Either the achromatic or monochromatic X-ray source can be employed to acquire the selected area spectra

- Automated aperture and iris in the electrostatic lens column help in forming a virtual probe at the surface of the sample

- Enhanced X-ray illumination for better performance of the selected area

- Pre-defined small spot analysis regions, smallest analysis area 15 μm diameter

- μ-boost acquisition mode for extremely high sensitivity at small area mode (option)

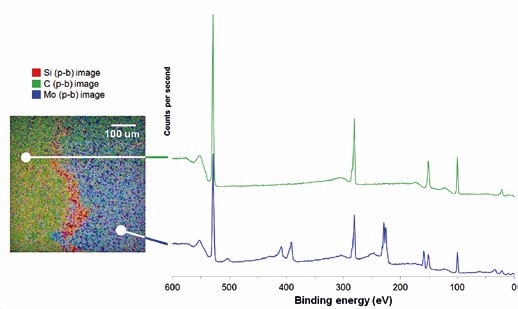

XPS image used to define a position for 27-μm selected area survey spectra.

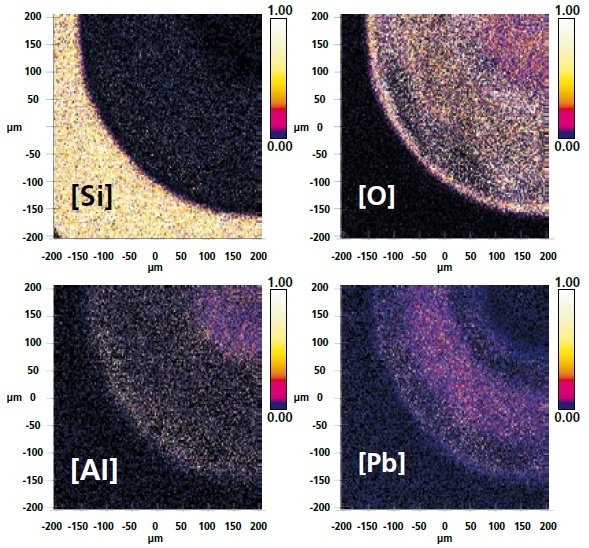

Fast Parallel Imaging

XPS imaging is also utilized to measure the lateral distribution of chemistry or elements at the surface. The AXIS Supra+ acquires rapid and high-spatial-resolution parallel images. The advantage of parallel image acquisition is that it is substantially faster and attains higher spatial resolution when compared to the more standard rastered beam technique.

Moreover, parallel imaging can be integrated with stage movements to achieve a “stitched” image, capable of producing images over several millimeters with a spatial resolution of several microns.

Parallel imaging provides the following capabilities:

- High-energy resolution, chemical-state imaging

- Ultimate spatial resolution of 1 μm at maximum magnification

- Quantitative imaging - the special spherical mirror analyzer and also the delay-line detector can give quantitative chemical-state images

- Spectromicroscopy - Spectra can be effortlessly acquired from image datasets, and a spectrum can be acquired at each pixel

Quantitative images where the color scale represents a relative amount of each element present at the surface.

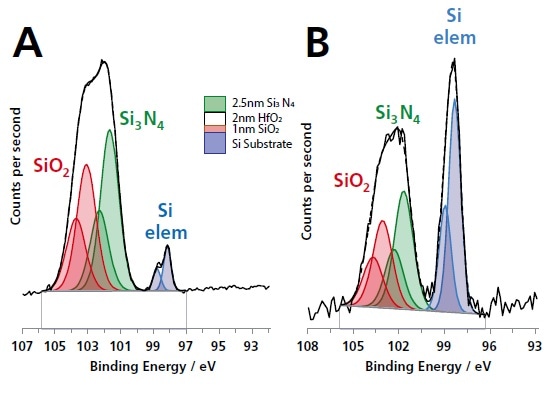

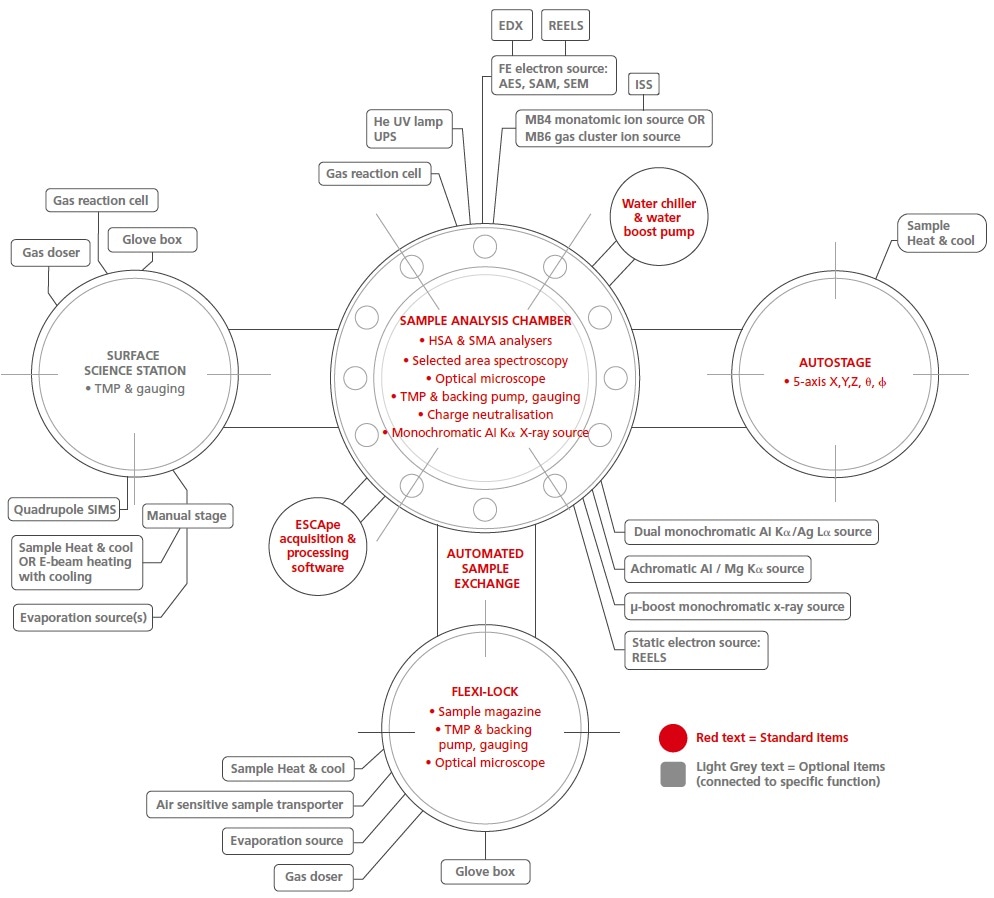

Multi-Technique Capability

Optional excitation sources contain a high-energy Ag Lα monochromated X-ray source, an achromatic Al/Mg X-ray source, as well as an enhanced helium discharge lamp for ultraviolet photoemission spectroscopy (UPS). In addition, the inclusion of a field-emission electron source adds scanning auger mapping (SAM), auger electron spectroscopy (AES), and secondary electron microscopy (SEM) ability to the instrument. These supplementary methods are coincident with the XPS analysis position offering a complementary understanding of the sample. Specifically, the inclusion of these methods does not have an impact on the performance of the market-leading XPS.

Options such as surface modification and sample preparation can be fitted on the introduction chamber, also referred to as Flexi-lock. Such options include a broad spot ion source, air-sensitive sample transporter, sample heat and cool, crystal cleaver, and glove box.

Users can configure a third chamber to offer a dedicated UHV setting for surface science research. Customary configuration equips the third chamber with a manual stage, and also optional characterization methods like quadrupole secondary ion mass spectrometry (SIMS), inverse photoemission spectroscopy (IPES), and low-energy electron diffraction (LEED).

Si 2p spectra acquired from a thin-film multilayer sample (courtesy of IMEC) shown in the schematic figure using (A) monochromated Al Kα radiation and (B) monochromated Ag Lα. The greater information depth of the Ag Lα excited Si 2p spectrum is demonstrated by the larger Si elemental substrate component.

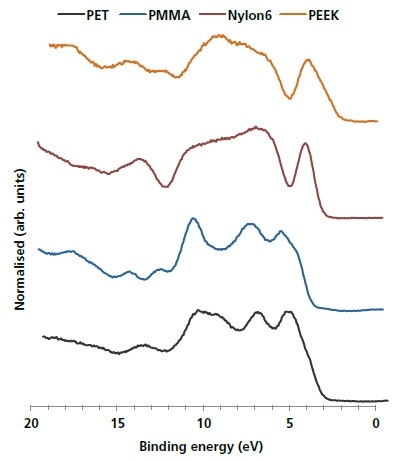

He II excited UPS valence band spectra of four common polymers.

Into the Bulk - Ion Sputter Sources

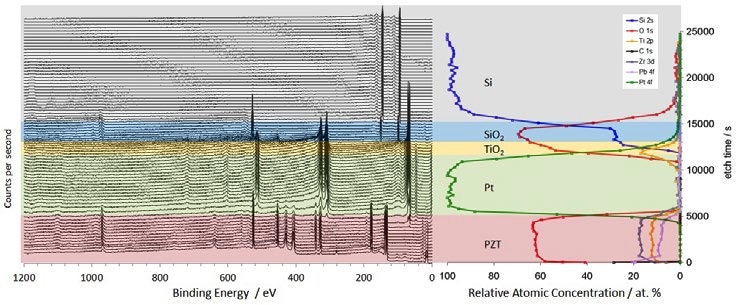

The AXIS Supra+ can be configured with the Minibeam 6 Arn+ gas cluster ion source (GCIS) or the Minibeam 4, high flux Ar+ monatomic ion source. Both these ion sources are fully incorporated into the ESCApe acquisition software for depth profile experiments or sputter cleaning. Also, gas handling is completely automated for sputter profiling and contains pump/purge sequences to allow the transition to helium gas for ion scattering spectroscopy (ISS).

The Minibeam 6 Arn+ is a multi-mode ion source that can function in Ar+/He+ monatomic ion mode or Arn+ cluster mode, as preferred. The latest development of gas cluster ion sources presents new opportunities for depth profiling organic materials with retention of chemistry across the profile. Moreover, depth profiles through intricate multi-layer materials like flexible electronic devices and organic LEDs can now be achieved with Arn+ cluster ions.

The Minibeam 6 can create 20 keV Arn+ cluster ions, and this special capability has led to the successful etching of inorganic materials like titanium dioxide with substantially less chemical damage induced by ions.

The Minibeam 4 ion source is supplied where cluster ion depth profiling is not needed. It works with variable beam energies from 500 eV to 4 keV. The design generates a high ion flux at low energy for enhanced interface resolution while retaining a high sputter rate.

- Automated introduction of gas and regulation of pressure

- Both sources can operate with He+ ions for optional ISS mode

- An option of monatomic or multi-mode gas cluster ion sources

Sputter depth profile survey spectra (left) and elemental concentration as a function of etch time (right) through a PZT/Pt/TiO2/SiO2/Si multilayer sample using 20 keV Ar500+ ions.

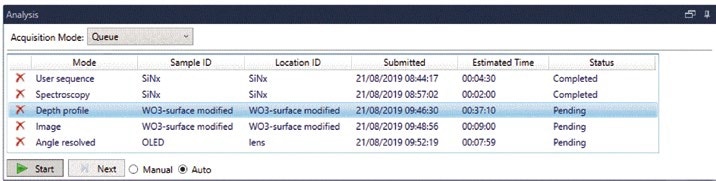

Unrivaled Instrument Automation

Sample handling is completely automated in the AXIS Supra+ instrument, making it stand out from other spectrometers. The automatic exchange of samples toward the end of an experiment permits continuous operation. Unmatched levels of automation extend to regular maintenance aspects like computer-controlled bake-out and further degassing of filaments.

Furthermore, automation includes the monochromator mirror and X-ray source, so that calibration and switching between the Al Kα source and the optional Ag Lα excitation source are entirely controlled by the computer. Continued optimized performance is also ensured by the motorized multi-position anode.

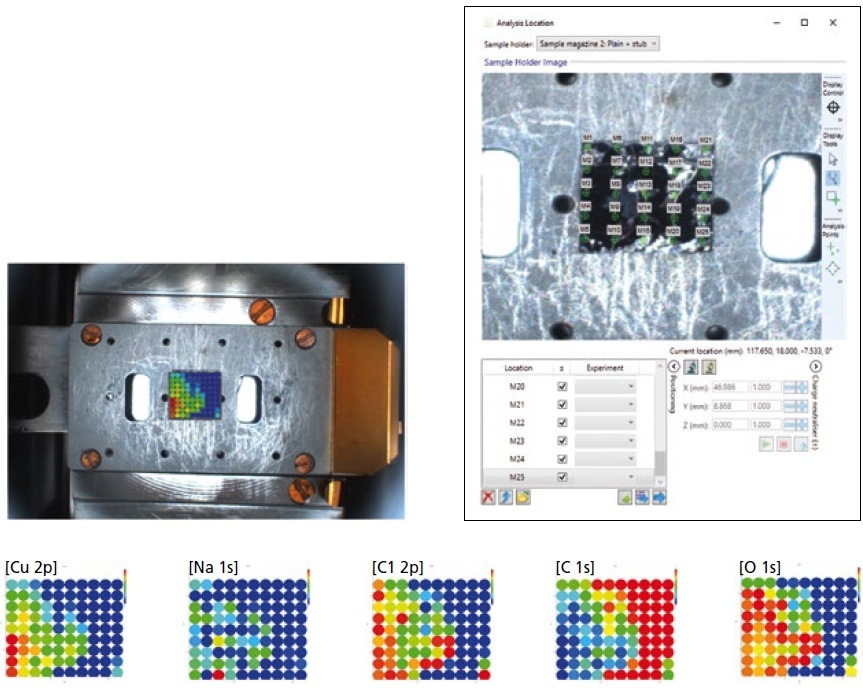

ESCApe is a versatile software developed to ensure that users’ interaction with the spectrometer is made as simple as possible, combining processing and acquisition to completely exploit hardware automation. The group array analysis capability within the ESCApe software is one example of this aspect. It is this functionality that enables users to drag an area over a sample and define a range of analysis points from which spectra are obtained.

Automated detection and quantification of peaks enable users to effortlessly produce a color concentration map of detected elements across the surface of the sample.

Group array analysis of an inhomogeneous distribution of Cu-nanoparticles on a graphite substrate. The color scale used to represent relative elemental concentration.

System Configuration Overview

Kratos Analytical’s AXIS Supra+ enables maximum levels of automation along with the flexibility to include complementary sample preparation and/or surface analytical methods. A number of optional items described below are now available as upgrades after the installation.

Kratos Analytical has an established track record in developing surface analysis instrumentation hardware. The company’s physicists and mechanical engineers can offer solutions for surface modification, sample handling, and further technique incorporation for the AXIS Supra+.

AXIS Supra photoelectron spectrometer

AXIS Supra (XPS) Surface Analysis Instrument