Sep 13 2009

Imagine a polka-dotted postage stamp that can sniff out poisonous gases or deadly toxins simply by changing colors.

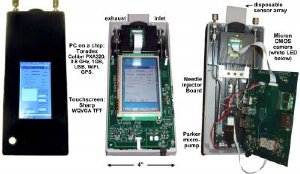

The handheld reader analyzes the color changes in the sensor array to quickly monitor the environment for toxic chemicals. Credit: Photo courtesy of Kenneth Suslick, University of Illinois.

The handheld reader analyzes the color changes in the sensor array to quickly monitor the environment for toxic chemicals. Credit: Photo courtesy of Kenneth Suslick, University of Illinois.

As reported in the Sept. 13 issue of the journal Nature Chemistry, Kenneth Suslick and his team at the University of Illinois have developed an artificial nose for the general detection of toxic industrial chemicals (TICs) that is simple, fast and inexpensive – and works by visualizing odors. This sensor array could be useful in detecting high exposures to chemicals that pose serious health risks in the workplace or through accidental exposure.

"Our device is simply a digital multidimensional extension of litmus paper. We have a six by six array of different nanoporous pigments whose colors change depending on their chemical environment," said Suslick, the Schmidt Professor of Chemistry at the U. of I. "The pattern of the color change is a unique molecular fingerprint for any toxic gas and also tells us its concentration. By comparing that pattern to a library of color fingerprints, we can identify and quantify the TICs in a matter of seconds."

To create the sensor array, the researchers print a series of tiny colored dots – each a different pigment – on an inert backing such as paper, plastic or glass. The array is then digitally imaged with an ordinary flatbed scanner or an inexpensive electronic camera before and after exposure to an odor-producing substance. And, unlike other electronic-nose technologies that have been tried in the past, these colorimetric sensors are not affected by changes in relative humidity.

While physicists have radiation badges to protect them in the workplace, chemists and workers who handle chemicals have no good equivalent to monitor their exposure to potentially toxic chemicals.

This project, which was funded by the National Institute of Environmental Health Sciences at the National Institutes of Health, exemplifies the types of sensors that are being developed as part of the NIH Genes, Environment and Health Initiative.

"This research is an essential component of the GEI Exposure Biology Program that NIEHS has the lead on, which is to develop technologies to monitor and better understand how environmental exposures affect disease risk," said NIEHS director Linda Birnbaum. "This paper brings us one step closer to having a small wearable sensor that can detect multiple airborne toxins."

To test the application of their color sensor array, the researchers chose 19 representative examples of toxic industrial chemicals. Chemicals such as ammonia, chlorine, nitric acid and sulfur dioxide at concentrations known to be immediately dangerous to life or health were included.

The laboratory studies used inexpensive flatbed scanners for imaging. The researchers have developed a fully functional prototype handheld device that uses inexpensive white LED illumination and an ordinary camera, which will make the whole process of scanning more sensitive, smaller, faster, and even less expensive. It will be similar to a card-scanning device. The device is now being commercialized by iSense, located in Palo Alto, Calif., and Champaign.

The researchers say older methods relied on sensors whose response originates from weak and highly non-specific chemical interactions, whereas this new technology is based on stronger dye-analyte interactions that are responsive to a diverse set of chemicals. The power of this sensor to identify so many volatile toxins stems from the increased range of interactions that are used to discriminate the response of the array.

"One of the nice things about this technology is that it uses components that are readily available and relatively inexpensive," said David Balshaw, Ph.D. program administrator at NIEHS. "Given the broad range of chemicals that can be detected and the high sensitivity of the array to those compounds, it appears that this device will be particularly useful in occupational settings."