Ohio State University engineers have developed a microscopic lens that allows objects to be viewed from nine different angles to create a three dimensional effect. The single lens is stationary that causes three dimensional images on its own.

Ohio's 3D Microscope

Ohio's 3D Microscope

According to Allen Yi, associate professor of integrated systems engineering at Ohio State, and postdoctoral student Lei Li, the lens will help develop microelectronics and medical devices. The research report has been published recently in the Journal of the Optical Society of America A.

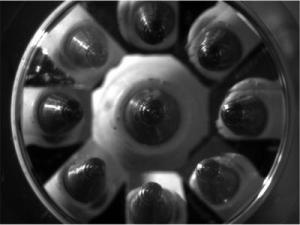

The sample thermoplastic lens was crafted on a precision cutting machine, but it could be produced cost -effectively with standard molding methods. It is as big as a fingernail and resembles a gem prepared for a ring. It has a flat top circled by eight facets. It is asymmetric. The facet sizes and angles differ in minute ways invisible to the naked eye. It is known as a freeform lens. A specially written computer program helped the team develop the lens to photograph microscopic objects through freeform optics.

A milling tool having a diamond blade was used to cut the shape from a piece of the thermoplastic polymethyl methacrylate, which is a transparent plastic also called acrylic glass. Plastic bits were chipped from the lens in multiples of 10 nanometers.

The final product looked like a rhinestone. Though it had a faceted top, its bottom was flat and wide. It was fitted on a microscope that had a camera pointed down through the facets, focusing on nano-sized objects placed under the flat side. Each facet captured a different image of the same object, the whole blended into a three-dimensional image on the computer. The use of the single lens will simplify future machine vision equipment designs.

Source: http://www.osu.edu/