North Carolina State University scientists have studied the feasibility of the “spincasting” technique to produce thin films of nanoparticles on an original substrate.

The centrifugal force is used in this spincasting method to dispense a liquid onto a solid substrate. Electronics industry makes use of this technique to create transistors by depositing organic thin films on silicon wafers.

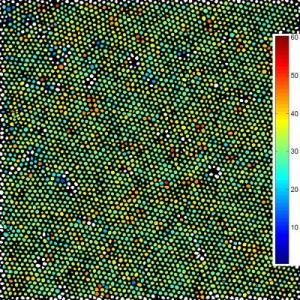

This is an orientation map of a spin-cast array of FePt nanoparticles. Most nanoparticles are enclosed by a hexagon of six neighboring nanoparticles. Each nanoparticle was color coded according to the angle (in degrees) of the hexagon's orientation. Nanoparticles colored white were identified as defects, because they had four, five, seven or eight "nearest neighbors" -- rather than six.

This is an orientation map of a spin-cast array of FePt nanoparticles. Most nanoparticles are enclosed by a hexagon of six neighboring nanoparticles. Each nanoparticle was color coded according to the angle (in degrees) of the hexagon's orientation. Nanoparticles colored white were identified as defects, because they had four, five, seven or eight "nearest neighbors" -- rather than six.

First, the scientists dissolved ligands-coated magnetic nanoparticles into a solution. These small organic molecules, which attach straight to metals, will help even nanoparticles distribution in the solution and on the substrate.

The drop of the solution was placed on the silicon chip, which is coated with a silicon nitride layer. The nanoparticle solution spreads over the surface of the chip when it is rotated at high speed. A thin nanoparticle layer remains on the substrate surface when the solution dries.

The scientists are capable of creating a structured layer of nanoparticles on the substrate covering an area of few square microns, by this technique. The potential results obtained helps in further research.

Spincasting is a rapid way of depositing a layer of nanoparticles and also has a commercial potential to create nanoparticle thin films economically.

This approach also needs some modifications to coat larger surface area with nanoparticles. Further research is necessary to alter the technique to accomplish a more even distribution.

Scientists have adapted some graphical tools to analyze the transmission electron microscopy images of the nanoparticle films. These tools have capability to spot and emphasize flaws in the crystalline structure of the layer.

Source: http://www.ncsu.edu/