According to UK chemists, improving the catalytic activity of gold nanoparticles can be a very simple process. When gold nanoparticles are washed using hot water, it removes ligands from the gold resulting in a clean metallic surface with active sites that are freely accessible.

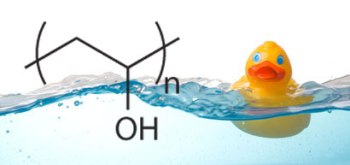

A simple hot water wash can scrub gold nanoparticles clean of polyvinyl alcohol ligands leftover from production

A simple hot water wash can scrub gold nanoparticles clean of polyvinyl alcohol ligands leftover from production

Graham Hutchings of Cardiff University with a team of co-workers developed this technique. The team has developed gold nanoparticle catalysts that are surface-supported. The technique involves pre-forming gold nanoparticles in a colloidal solution prior to deposition on a support and allows accurate control over particle structure and dimension.

A coating of stabilizing polyvinyl alcohol (PVA) ligands ensures that the nanoparticles do not clump together in solution. However, the performance of the nanoparticles when it is fixed to a solid support will be affected by ligands. Earlier, the ligands were removed by heating nanoparticles up to 400C. This process affected the surface of metal causing sintering. At such high temperatures, the nanoparticles start to coalesce, and the catalytic activity decreases. It was proved that the catalytic activity of surface-supported gold nanoparticles was improved and the PVA was removed when treated with 90C water for duration of one hour.

Most metals would undergo corrosion when treated with hot water. Hutchings stated that organic solvents could be used for surface-supported nanoparticles instead of water. The research work is proof to the fact that there is a simpler option to removal of ligands than subjecting them to high temperatures.