Nature Nanotechnology has published a paper describing the research work done by the University of Illinois in producing metamaterials. John Rogers, materials engineering professor, head of the research team, has explained the use of nanotransfer printing technique for the stamping of 3-D negative index metamaterials (NIMs) onto glass or a plastic. This process can be used for developing products such as an invisibility cloak or an extremely high resolution lens.

Metamaterials

Metamaterials

Materials which are capable of bending light rays in different ways not possible by natural materials are called metamaterials. They are made up of several layers with small spaces in every layer such that on combining the layers, a mesh is formed that causes the light rays to bend in different ways. For example, consider arranging several screen doors one above the other in an unordered line. When light is passed through different layers of the screen door, it gets reflected in various directions. The mesh holes of metamaterials are of the size of the wavelength of light which is very small. This property has prevented it from being used for other purposes apart from research. The new innovative method intends to overcome these drawbacks.

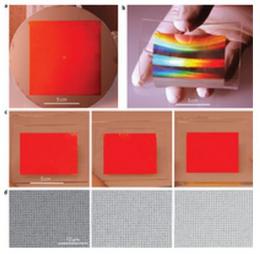

The conventional method of developing metamaterials directly through electron beam etching is replaced by a stamping technique wherein a stamp is first developed. The stamp consists of tiny valleys and peaks and is coated with a removable layer of nondescript material. It is then coated with magnesium fluoride and silver layers. The mesh is formed by making the coating from the stamp peaks to stick on to a plastic or a glass sheet from which by etching process the sacrificial layer is removed leaving behind the mesh pattern alone.

With the available devices in lab, the research team applied this process to produce metamaterials with a size of few square inches. Rogers is expecting his team to produce metamaterials of larger magnitude.