According to a research conducted by the University at Buffalo engineers, the smallest bridge of gold consisting of just one atom exhibits considerably high-strength characteristics.

A bridge made of a single atom of gold has twice the strength of bulk gold, according to new UB research.

A bridge made of a single atom of gold has twice the strength of bulk gold, according to new UB research.

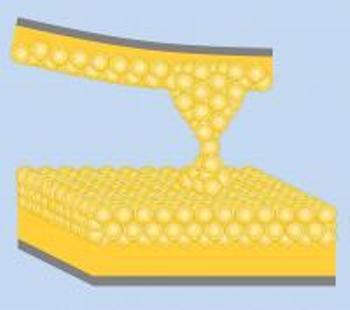

The experiments revealed the properties of necks of gold at the atomic scale, produced by pressing the sharp, gold edge of a cantilever into a flat surface of gold.

When these small, gold bridges were inspected, it was observed that they were most rigid when they were made up of only one atom. The details of study were recorded in Physical Review B in June by a team of researchers in UB's Department of Mechanical and Aerospace Engineering. The team also found that sudden atomic displacements take place as the surface and gold tip are separated. The atomic displacements are not random, but are based on specific principles of crystallography.

Engineers at the Laboratory for Quantum Devices in UB are trying to map the growth of samples from a single atom to a large number of atoms and to track the physical properties of such samples including magneto-transport, magnetic and mechanical behavior. This complex task can be implemented using advanced technology which traps a single or a couple of atoms within probes, and conducts push and pull on the atoms to observe their changes.

The complex technology developed to conduct the research was licensed to Precision Scientific Instruments. The President and cofounder of Precision Scientific Instruments, Gerry Murak, stated that these techniques and devices are exceedingly accurate and can change the shape of sample in the order of picometers. This results in simultaneously elongating the bond lengths and studying the forces at the piconewton scale and several other properties. The advanced technology could accelerate advancements in fields such as satellite communications and health care, says Murak. He added that Metrology systems with the capacity to determine the behavior of atomic-scale equipment are in demand, and this technology provides users a specialized platform.