MIT Researchers have developed a liquid-based method to accurately form submicroscopic wires in water, which enables fabrication of complete electronic devices via a liquid-based procedure.

The method is termed as hydrothermal synthesis and was demonstrated by creating an operational light-emitting diode (LED) array with nanowires of zinc oxide in a microfluidic channel. They utilized a syringe to force solution via a capillary tube that had a width of only a tenth of a millimeter. The researchers did not use any costly semiconductor manufacturing facilities and processes.

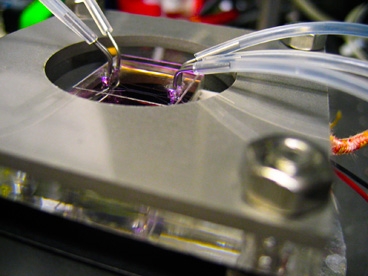

Zinc oxide nanostructures are directly synthesized in parallel microfluidic channels (held by the metal frame) by flowing reactants through the tubing.

Zinc oxide nanostructures are directly synthesized in parallel microfluidic channels (held by the metal frame) by flowing reactants through the tubing.

Unlike larger structures, the shape of nanomaterials when varied can lead to significant changes in behavior. Brian Chow is co-author of a paper that explains these findings, which was recorded in the journal Nature Materials. The system developed by Chow and his coworkers can accurately alter the nanowires’s aspect ratio to produce flat plates or long, thin wires. Chow explains that there are alternate ways for producing nanowires.

Researchers have revealed techniques to manipulate the morphology of wires, especially in organic solvents and at high temperatures. It is the first time that researchers have found a way to do the same in water at low-temperatures as it may be easy to construct such equipment on plastics and flexible polymers, he added.

Researchers had to determine the electrostatic characteristics of zinc oxide as it evolves from a solution. When the ions of various compounds are mixed with the solution, they electrostatically adhere to the sides or the ends of the wire, thus restricting the growth of wires in those directions. The extent to which the growth is inhibited is based on the properties of the compounds.

The MIT scientists predict that they can use other materials to control the shape of the wires. A senior research scientist at Dow Chemical, Jaebum Joo says that they can use titanium dioxide to control the shape of the solar cells. As the benign conditions enable the material to be evolved on surfaces of plastic, he says, it could lead to the development of flexible display panels.

Other key applications that use zinc oxide material include sensors, batteries, and optical equipment. Joo says the processing technique is critical for bulk manufacturing.

The team also aims to use the technique to manufacture spatially complex equipment from biocompatible polymers. Joo adds. These could be used to produce small equipment that could be incorporated in the brain to offer long-term, high-resolution stimulation and sensing.