Researchers from University of Cincinnati (UC) have launched a disposable, economic lab-on-a-chip sensor to offer rapid feedback on the presence and levels of heavy metal particularly manganese in humans than existing technologies found in health-care centers.

The sensor will be subjected to field testing in Marietta, Ohio. The discovery was published in an international journal named Biomedical Microdevices.

UC researchers have developed the first lab-on-a-chip sensor to provide fast feedback regarding levels of the heavy metal manganese in humans.

UC researchers have developed the first lab-on-a-chip sensor to provide fast feedback regarding levels of the heavy metal manganese in humans.

UC sensor technology will be utilized in point-of-care testing devices that offer immediate feedback within 10 minutes. It is anticipated that the UC sensor will be efficient for large-scale applications in research, occupational, and clinical settings, such as testing children for nutrition deficiencies.

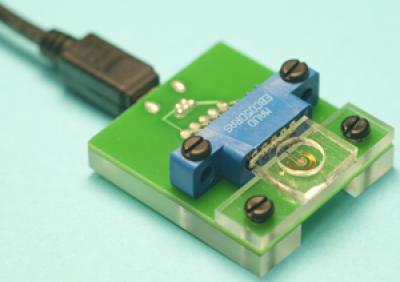

This new sensor is regarded as eco-friendly as the integrated working electrode is built using bismuth instead of carbon or mercury. It is regarded as child-friendly as it needs just one or two droplets of blood sample for performing the test which previously required 5 ml of sample. This sensor is based on a technology known as anodic stripping voltammetry that combines three electrodes including an auxiliary electrode, a reference electrode, and a working electrode.

Detecting an electronegative metal like manganese is difficult because of the occurrence of hydrolysis at the auxiliary electrode that rigorously restricts a sensor's detecting ability. The process wherein a molecule splits into two parts when a water molecule is added is termed as hydrolysis. Thin-film bismuth used in working electrodes helped to solve this issue.

Further, the working-electrode surface and the sensor layout were optimized by the research team to decrease the impact of hydrolysis and increase the sensitivity and reliability in identifying heavy metals. The sensor layout is such that it strips the heavy metal from the blood serum and later measures the level of heavy metal. The final result is the first-in-use lab-on-a-chip that constantly detects the levels of manganese in humans.