Research teams at Rensselaer Polytechnic Institute (RPI) have collaborated with the University of Wollongong, Australia to develop a nanomaterial to collect wasted heat from industrial processes and electrical devices and convert it into electricity.

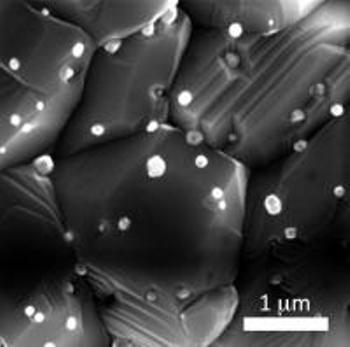

Engineering researchers at Rensselaer Polytechnic Institute have developed new thermoelectric nanomaterials, pictured above, that could lead to techniques for better capturing and putting this waste heat to work.

Engineering researchers at Rensselaer Polytechnic Institute have developed new thermoelectric nanomaterials, pictured above, that could lead to techniques for better capturing and putting this waste heat to work.

The process of recycling heat offers great potential for harvesting power and increasing the efficiency of all electrical devices. The process of recycling heat requires a material that has high electrical conductivity and low thermal conductivity.

Researchers at RPI have discovered that zinc oxide can be used for this process. However, zinc oxide naturally has high levels of both electrical and thermal conductivity. This quality can prove to be a hindrance in converting waste heat to electricity as lowering one property of the material without affecting the other is a very difficult process. Researchers have addressed this problem by adding tiny amounts of aluminium to zinc oxide and processing the combined materials in a regular microwave oven. Through this method, the research team was able to create enough nanomaterial that can be used to make a miniature equipment measuring a few centimetres. Instead of the regular methods where nanomaterials are created on substrates, the new inexpensive process has the ability to create pellets of the nanomaterial that can in turn be a used on any surface.

This method can also be scaled up for industrial production to create greener power plants, aircrafts, cars and other systems and devices. The research was funded by IBM, University of Wollongong, Australian Research Council, Rensselaer Nanotechnology Centre and S3TEC which is US Department of Energy Office of Basic Energy Science funded Energy Frontier Research Centre