Imec, a nanoelectronics research company, has developed a CMOS integrated polycrystalline SiGe piezoresistive pressure sensor.

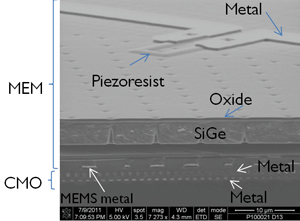

Cross-section SEM picture of the integrated sensor. At the bottom, the two Cu metal lines of the CMOS circuit can be observed. Above, the MEMS layers (the poly-SiGe membrane and piezoresistors, the oxide sealing layer and the metal interconnects) are visible.

Cross-section SEM picture of the integrated sensor. At the bottom, the two Cu metal lines of the CMOS circuit can be observed. Above, the MEMS layers (the poly-SiGe membrane and piezoresistors, the oxide sealing layer and the metal interconnects) are visible.

When compared to poly-Si, polycrystalline SiGe holds more promise as a MEMS structural material. It allows post-processing on top of a CMOS with 0.13 µm Cu-backend. This gives the required mechanical properties at lesser temperatures. The MEMS-last approach enables integration of the MEMS without any changes in the normal CMOS foundry processes and facilitates smaller die areas. Poly-SiGe provides a more flexible and generic technology for CMOS-MEMS monolithic integration.

Imec had earlier proved the abilities of poly-SiGe for MEMS over aluminum-backend CMOS integration, and has now replaced aluminum with copper. The Imec sensor has four poly-SiGe piezoresistors, an instrumentation amplifier made using 0.13 µm CMOS technology, a piezoresistive pressure sensor which has been surface-micromachined, tungsten-filled vias, oxide dielectric and Cu- interconnects. The maximum processing temperature of the sensor is maintained below 455ºC to facilitate the CMOS integration. The process includes addition of a passivation layer for safeguarding the electronic circuit from the deposition and etching steps required for fabricating MEMS devices. The MEMS processing does not deteriorate the CMOS circuit. The poly-SiGe piezoresistive sensor demonstrated approximately 2.5 mV/V/bar sensitivity and when it was integrated with the Cu-based CMOS amplifier it demonstrated 64 times more sensitivity of 158 mV/V/bar.