National Institute of Standards and Technology and Colorado Boulder University have jointly designed a microchip, which uses microfluidics and switch controlled magnetic pulses to collect and transfer magnetic beads that have unique applications in medical diagnostics and biotechnology.

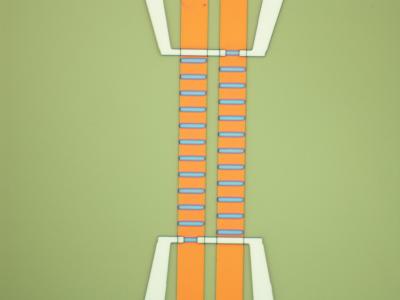

This micrograph of a magnetic microfluidic chip was developed by the National Institute of Standards and Technology and University of Colorado Boulder. Brief pulses of electrical current in the two orange lines generate a magnetic field to turn individual spin valves (blue bars) on and off, moving a magnetic bead up or down the "ladder." Credit: W. Altman/CU and NIST

This micrograph of a magnetic microfluidic chip was developed by the National Institute of Standards and Technology and University of Colorado Boulder. Brief pulses of electrical current in the two orange lines generate a magnetic field to turn individual spin valves (blue bars) on and off, moving a magnetic bead up or down the "ladder." Credit: W. Altman/CU and NIST

The potential application of using magnetic beads as form of a carrier for biomolecules like DNA is possible using this switch and trap mechanism similar to a MRAM. Microfluidic systems usually comprise of pumps and micro valves to move molecules and other fluids in various channels. The MRAM design-based micro chips usually require uninterrupted power supply however leading to overheating that causes damage to the molecules.

To overcome this problem, NIST/CU came up with two lines of 12 thin-film optimized magnetic spin valves also known as magnetic switches that trap the magnetic beads in a side by side setting. Electric pulses are given to these magnetic spin valves to trap the magnetic beads while the system is in powered “On” and release the same in the “Off” mode. These magnetic beads are suspended in saltwater solution above the valves prior to setting themselves in the stacked array. To overcome the heating problem, the team has utilized permanent magnets that carries on the function even in the absence of electric pulses thereby not letting the system to be get heated as in the conventional case. The power requirement is for less than a micro second.

In the future some of these programmable micro fluidic chips can be used to magnetically tag proteins and DNA using smart tags with distinct properties such as magnetic markers for applications in MRI and other portable medical diagnostic devices using these magnetic spin valves.