Scientists at the Nanotechnology Research Center of the Georgia Institute of Technology have for the first time directly compared two basic techniques that can be utilized for chemically doping two-dimensional graphene sheets for the production of interconnects and devices.

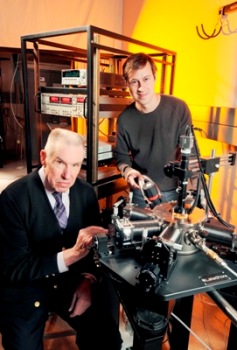

James Meindl (left), director of Georgia Tech’s Nanotechnology Research Center, and graduate research assistant Kevin Brenner observe the processing of graphene in a cryogenic probe station. The researchers have compared two fundamental techniques for doping graphene. Credit: Georgia Tech Photo: Gary Meek

James Meindl (left), director of Georgia Tech’s Nanotechnology Research Center, and graduate research assistant Kevin Brenner observe the processing of graphene in a cryogenic probe station. The researchers have compared two fundamental techniques for doping graphene. Credit: Georgia Tech Photo: Gary Meek

According to the study, graphene doping can be done with the combination of other processes and must be applied only to the tip of nanostructures being produced. The researchers assessed the efficiency of two diverse techniques utilizing exfoliated graphene sheets. During the study, they coupled a usual resist material with electron-beam lithography for edge passivation and coated the material surface for adsorption.

The scientists discovered that the edge treatment, which reacts chemically with imperfections formed during the cutting of material, generates carriers in the sheets of graphene at an efficiency which is thousand folds higher than that of surface treatment. Kevin Brenner, one of the researchers, commented that since the work is applied to the material edges, it eliminates imperfections and makes the center perfect. This method is able to retain the unique properties and extremely quick movements of graphene, while generating extremely high carrier densities, he added.

The researchers used a hydrogen silsesquioxane thin film for doping the edges of a graphene sheet and then utilized electron beam lithography for cross-linking the nanostructure by bonding oxygen atoms to the tips, resulting in the formation of a p-type doping. Brenner stated that plasma etching can also be used for the doping process. By performing the process in a setup comprising specific atoms or manipulating the specific atoms utilized in the plasma, these atoms can be pinned to the edges.

Besides producing electronic devices, the researchers plan to use graphene as a replacement for copper in interconnects. With the fundamental data about graphene doping, the scientists plan to fabricate devices to investigate the performance of the innovative material.