The University of Maryland (UMd) in partnership with a multi-institute team of scientists has developed an innovative alloy material through the combination of advanced material research and a very old metallurgy process, paving the way to produce magnetic micromechanical devices and sensors.

The novel alloy material demonstrates ‘giant magnetostriction,’ a phenomenon that represents amplified dimensional changes in a material when it is placed in a powerful magnetic field. This phenomenon is comparable with the well-known piezoelectric effect that makes materials such as quartz shrink in the presence of an electric field. However, contrary to piezoelectric materials, magnetostrictive materials eliminate the requirement of wires and can be manipulated by an exterior magnetic field source.

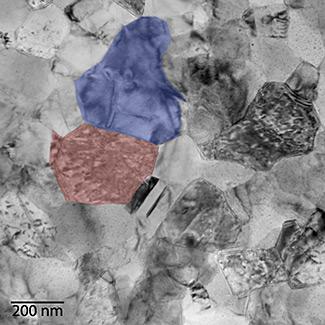

Transmission electron microscope image taken at NIST of an annealed cobalt iron alloy. The high magnetostriction seen in this alloy is due to the two-phase iron-rich (shaded blue) and cobalt-rich (shaded red) structure and the nanoscale segregation. (Credit: Bendersky/NIST)

Transmission electron microscope image taken at NIST of an annealed cobalt iron alloy. The high magnetostriction seen in this alloy is due to the two-phase iron-rich (shaded blue) and cobalt-rich (shaded red) structure and the nanoscale segregation. (Credit: Bendersky/NIST)

The innovative alloy, made of iron and cobalt, demonstrates these unique properties without the addition of rare-earth metals. The researchers utilized a combinatorial sorting method to identify the best combination of processing and metal proportions. They have created numerous small test cantilevers with various sizes and applied a thin film alloy coating over them by steadily changing the proportion of cobalt to iron all along the sequence of cantilevers. They also employed two types of heat treatments. One method involves the heating of the alloy material to an annealing temperature followed by sudden quenching in water.

The Stanford Synchrotron Radiation Lightsource (SSRL) and NIST have accurately measured the structures and mechanical properties of the novel material. Based on the data, the best-performing alloy has an intricate hetereogenous, nanoscale structure wherein cobalt-rich crystals were entrenched across a unique, iron-rich crystal form.

Magnetostriction of the alloy was calculated by gauging the magnitude of bend caused by the alloy on the small silicon cantilever in the presence of a magnetic field and using NIST’s measurement to gauge the cantilever’s hardness. The optimum-annealed alloy demonstrated a significant magnetostriction effect in a magnetic field down to 0.01 T.

NIST’s Will Osborn stated that the quenched alloys may offer processing and size benefits over piezoelectric microdevices. These metal alloys are future-generation material for MEMS devices, Osborn said.