Researchers at Rensselaer Polytechnic Institute (RPI) and Rice University conducted a study, which established that silicon, copper and gold become wet even when they are covered with a single graphene layer. The study, which was published in Nature Materials, is important for scientists who are exploring to advance surface coatings for various applications.

Graphene is the thinnest material known to science

Graphene is the thinnest material known to science

According to Pulickel Ajayan, Rice University's Benjamin M. and Mary Greenwood Anderson Professor in Mechanical Engineering and Materials Science and Chemistry, the intense thinness of graphene makes it a complete non-invasive coating. A water droplet on a surface can see through the layers of graphene and conforms to the wetting forces below the surface. This phenomenon is not seen in other coatings which reinforces that graphene is special in many ways.

Ajayan and Nikhil Koratkar, a professor of mechanical, aerospace and nuclear engineering at RPI, are .principal investigators of the study.

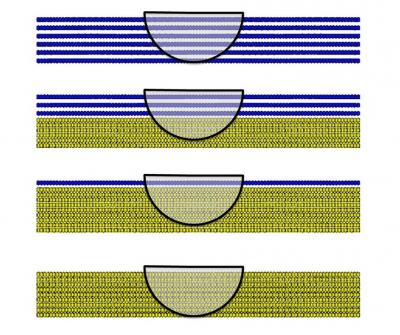

Ajayan stated that a standard surface of graphite, which is generally known as pencil lead, can be hydrophobic. However, in the current research, the scientists found that a carbon lattice’s single-atom-thick layer presents a minor hindrance between a hydrophilic surface and water. Wetness is reduced when more layers are piled and at about six layers, graphene turns into graphite.

Ajayan said that the remarkable feature of the study is the capability to alter such surface properties into conductivity while at the same time maintaining the wetting characteristics. Since pure graphene is known to be highly conductive, the findings can help in developing an innovative range of conductive, but waterproof surface coatings. Applications like condensation heat transfer will benefit significantly from this discovery.

Copper, which has high thermal conductivity, corrodes easily. The researchers coated a graphene layer on a copper sample and discovered that the subnanometer barrier guarded the copper from oxidation without affecting its interaction with water. It also improved the thermal effectiveness of copper by 30% - 40%.