Javier Atencia from the National Institute of Standards and Technology (NIST) has developed a low-cost and simple-to-construct microfluidic system, a diffusion-based gradient generator capable of rapidly evaluating the impact of varying concentrations of certain chemicals on live cells.

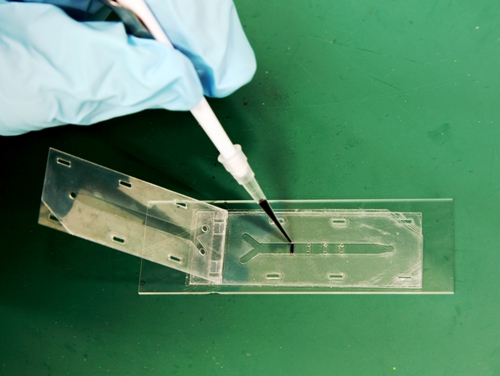

NIST researchers have combined a glass slide, plastic sheets and double-sided tape to create an inexpensive and simple-to-build microfluidic device for exposing an array of cells to different concentrations of a chemical. (credit:Cooksey/NIST)

NIST researchers have combined a glass slide, plastic sheets and double-sided tape to create an inexpensive and simple-to-build microfluidic device for exposing an array of cells to different concentrations of a chemical. (credit:Cooksey/NIST)

The NIST system has two unique advantages over conventional microfluidic cell assay systems. The first advantage is that the system is based on diffusion phenomenon that considerably decreases the risk of cells being damaged or swept away due to shearing forces created in the test fluid.

Simplicity is the second big advantage of the NIST system. The device is constructed in layers with each part accurately placed with an alignment tab. Glass slide is the base upon which is bonded a double-sided tape strip that is cut to have a row of four channels of micrometer size. The next layer is a polystyrene strip cut that have two lines with each having four small circular wells and each pair lines up with the tips of the channel underneath it. Atop this goes another double-sided tape strip that has a Y-shaped canal cut to act as a flow path for a chemical gradient, a solution where the concentration of the chemical varies gradually and as expected across an array of cultured cells. The last layer, Mylar strip is cut to have a similar Y-canal to act as a cover.

NIST Chip-Scale Assay: A Simple Way to Study Cells

Through this hinged cover, the wells are allowed to add test cells. After adding the test cells, the cover is affixed to seal the gradient generator. Magnetic connectors, Atencia’s another innovation, are used to control the fluid flow inside the system. At constant pressure, this flow ensures a steady-state stream via the device and generates a diffusion gradient in every buried channel. Exposure of cells in the channels to an array of chemical concentrations occurs concurrently.