Optomec and Stratasys have declared the completion of a joint development project, in which printed electronics and 3D printing were used to fabricate the first-of-its-kind fully printed hybrid structure.

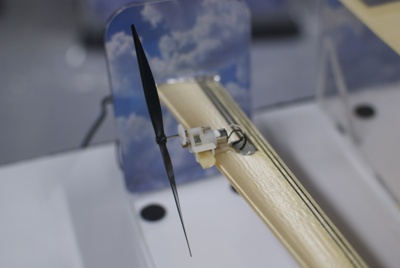

Additive manufacturing first: Electronic circuitry was printed onto a model of a UAV wing, which itself was 3D printed. (Photo: Optomec & Stratasys)

Additive manufacturing first: Electronic circuitry was printed onto a model of a UAV wing, which itself was 3D printed. (Photo: Optomec & Stratasys)

In the first project, a ‘smart wing’ was developed for a prototype of an unmanned aerial vehicle (UAV) with functional electronics. This groundbreaking development shows promise to transform product development in a broad array of industries, including aerospace, automotive, consumer electronics and medical device.

Stratasys’ fused deposition modeling (FDM) process was utilized for three-dimensional printing on the wing of the UAV prototype, while Optomec’s aerosol jet system was utilized to print an antenna, circuitry and sensor directly onto the wing. UAV provider, Aurora Flight Sciences offered the sensor and electrical designs.

The combination of printed electronics and FDM 3D printing technologies is advantageous over conventional prototyping, production and field repair processes. 3D printers allow lighter and thinner mechanical structures, while conformal electronics printed straightaway onto the structures create free space for more payloads. These benefits make the process more eco-friendly and cost-effective as it consumes fewer materials.

David Kordonowy, who is the Head of Aerostructures Research Group at Aurora Flight Sciences, stated that the capability to create functional electronics directly into intricate structures utilizing additive manufacturing will help in rapid fabrication of customized UAVs.