A multi-institutional research team has developed a carbon nanotube sponge that is capable of absorbing oil spilled in water with an unprecedented efficiency using computational models created on supercomputers at the Oak Ridge National Laboratory.

A carbon nanotube sponge developed with help from ORNL researchers holds potential as an aid for oil spill cleanup.

A carbon nanotube sponge developed with help from ORNL researchers holds potential as an aid for oil spill cleanup.

The multi-institutional research team produced large carbon nanotube clumps by carefully replacing boron atoms into the carbon lattice. Researchers, Bobby Sumpter and Vincent Meunier performed the computational simulations to analyze the impact of boron addition on the structure of the carbon nanotube.

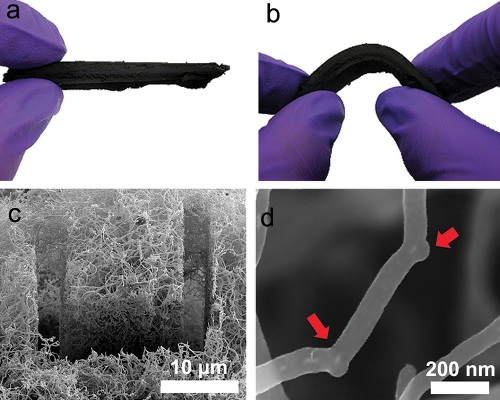

Sumpter explained that since the valence electron count of boron is different, the addition of boron causes drastic changes thus activating the nanotubes to grow into a three-dimensional network by promoting the creation of ‘elbow’ junctions. The resulting material is an interlinked, woven sponge-like substance, which is three-dimensionally strong due to the interconnection between the tubes when compared to a single-dimensionally strong nanotube.

Further studies demonstrated that the novel material is remarkably effective at soaking up oil spilled in seawater as it is oleophilic and hydrophobic. Sumpter informed that the novel material can soak up as high as 100 folds of its weight in oil based on the sponge network’s density and the oil to water content’s density, making it a promising oil spill cleanup technology. The material is strong enough to be used several times as it can soak up oil even when it is burned and is not get damaged when it is subjected to squeezing.

The spongy nanomaterial’s magnetic properties, due to the usage of an iron catalyst in the production of the nanotube, enable it to be controlled and extracted easily with the help of a magnet during oil cleanup, thus preventing the environment from getting degraded.