Silicon anode used in batteries gets destroyed within a few cycles due to the electrolyte attack and the strain of contraction and expansion.

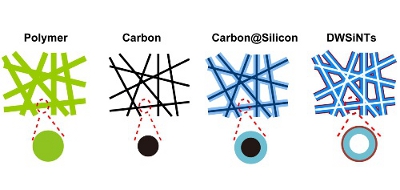

The new double-walled silicon nanotube anode is made by a clever four-step process: Polymer nanofibers (green) are made, then heated (with, and then without, air) until they are reduced to carbon (black). Silicon (light blue) is coated over the outside of the carbon fibers. Finally, heating in air drives off the carbon and creates the tube as well as the clamping oxide layer (red). (Image courtesy Hui Wu, Stanford, and Yi Cui)

The new double-walled silicon nanotube anode is made by a clever four-step process: Polymer nanofibers (green) are made, then heated (with, and then without, air) until they are reduced to carbon (black). Silicon (light blue) is coated over the outside of the carbon fibers. Finally, heating in air drives off the carbon and creates the tube as well as the clamping oxide layer (red). (Image courtesy Hui Wu, Stanford, and Yi Cui)

To overcome this issue, a research team headed by Yi Cui from the Stanford University and SLAC has developed a double-walled silicon nanotube that survives over 6,000 cycles, much higher than that required by mobile electronics or electric vehicles.

In the last five years, Cui’s team has used nanowires and hollow silicon nanoparticles to fabricate silicon anodes with an improved operating life. The new design, comprising a double-walled silicon nanostructure ceramic coated with a silicon oxide layer, paves the way to devise lighter, longer-lasting and smaller batteries.

The outer ceramic layer prevents the nanotube’s exterior wall expansion, thus making the nanotube to stay intact. However, the silicon expands inside the hollow interior, which is not big enough to allow the entry of electrolyte molecules. The resulting anode operated for over 6,000 cycles and retained its 85% capacity after the first charging cycle.

Cui informed that his next step is to simplify the production process of the double-wall silicon nanotubes. His team members are working on designing superior performance cathodes to work with the new anode to create a battery capable of demonstrating a performance five holds higher than present lithium-ion technology.

Cui formed a company named Amprius in 2008 to license rights for Stanford’s patents that cover his silicon nanowire anode technology. The company’s short-term goal is to fabricate batteries that have an energy density two folds higher than that of present lithium-ion batteries. The study findings have been reported in the journal, Nature Nanotechnology.