Peking University, Duke University (USA) and the Chinese Academy of Sciences have fabricated an ‘uncooled’ ultrasensitive photovoltaic infrared detector using single-walled carbon nanotubes (SWNTs).

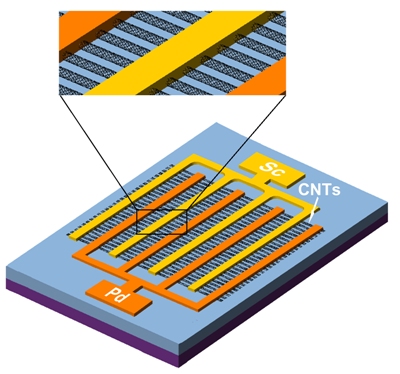

This schematic shows the design of single-walled carbon nanotube photodetector, which provides a more efficient method of collecting infrared radiation without relying on cryogenics for cooling. (Image courtesy Sheng Wang, Peking University.)

This schematic shows the design of single-walled carbon nanotube photodetector, which provides a more efficient method of collecting infrared radiation without relying on cryogenics for cooling. (Image courtesy Sheng Wang, Peking University.)

The researchers have reported about their new detector in Optical Materials Express, an open-access journal of the Optical Society. Sheng Wang, one of the researchers, informed that besides demonstrating superior optical, electrical and mechanical properties, carbon nanotubes are also suitable for infrared applications because their infrared light absorption capability can be adjusted through the selection of nanotubes with different diameters. The nanomaterial’s reaction to infrared light is very fast on the level of picoseconds, thanks to its high electron mobility. Hence, this carbon nanotube-based infrared detector is more efficient than a conventional infrared detector made of mercury-cadmium-telluride alloy.

The fabrication of this photovoltaic infrared detector involves the aligning of SWNT arrays over a silicon substrate. This structure is then positioned between asymmetric scandium and palladium contacts, which collectively form an Ohmic contact, a region where electrical resistance is very low. This arrangement enables the detector work more efficiently.

This new detector does not require electric or liquid nitrogen cooling thanks to the novel thermal properties of carbon nanotubes, which themselves release minimal infrared radiation, particularly when they placed over the substrate. Carbon nanotubes prevent heat upsurge in the detector as they are good heat conductors.

The novel detector illustrated satisfactory sensitivity at room temperature. The researchers reported that the detector’s sensitivity can be enhanced by increasing carbon nanotubes’ density. The detector demonstrates high infrared detection capabilities utilizing a few-nanometer-thick carbon nanotube films, one of its key benefits. Its fabrication process is well-suited with carbon nanotube transistors, thus providing a compatible platform for the fabrication of carbon nanotube-based electronic and optoelectronic ICs.

The innovative infrared detector holds potential for scientific, optical communications, manufacturing, military, and industrial applications. The team’s next move is to enhance the detector’s detection capability with higher SWNT density and obtain a broad spectrum response by controlling diameter efficiently.