Professor XI Ning from the Department of Electrical and Computer Engineering at the Michigan State University and Professor LIU Lianqing at the Shenyang Institute of Automation Chinese Academy of Sciences’ State Key Laboratory of Robotics have developed a novel cutting technique capable of cutting graphene with accurate control.

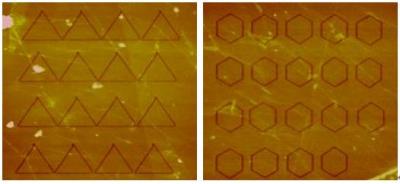

This shows graphene cutting results based on a nanorobot. ©Science China Press

This shows graphene cutting results based on a nanorobot. ©Science China Press

The novel mechanism has been developed on the basis of nanoscale force feedback and involves an atomic force microscope-based nanorobot. The research titled ‘Graphene Control Cutting Using an Atomic Force Microscope Based NanoRobot’ has been reported in SCIENTIA SINICA Physica, Mechanica & Astronomica. 2012, Vol 42(4).

The integration of robotics enables efficient nanomanipulation hence resolves the drawbacks of atomic force microscopy, which are low efficiency, requirement for real-time feedback, and inferior location ability. The researchers systematically investigated the correlation between nanocutting forces and lattice cutting directions by rotating the sample in the identical cutting conditions, including tip, efficient cutting surface of the tip, cutting velocity and load.

The researchers discovered that the cutting forces were associated with the graphene lattice’s cutting direction due to the asymmetry of the nanomaterial’s crystal structure, meaning that nanoscale forces can be utilized as a real-time feedback to provide a closed-loop mechanism that is capable of cutting graphene with accurate control. The cutting forces change with the cutting direction with a variation as high as 209.36 nN, in the same period.

This finding is the basis to develop a closed-loop fabrication strategy by utilizing real-time force as a sensor feedback to manipulate the cutting direction with lattice accuracy. This novel technique in combination with current parallel multi-tip technology can be used to produce large-scale, high-efficiency nanodevices based on graphene at a low cost.