Wafer level precision measurement solution provider, Cascade Microtech has unveiled its new and the industry’s first fully automatic measurement solution for high power devices at the wafer level.

APS200TESLA

APS200TESLA

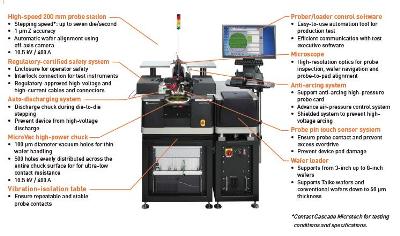

Labeled APS200TESLA, the device combines the capabilities of the company’s BlueRay production automation technology and Tesla on-wafer characterization measurement of power device technology.

The rise in demand for environment-friendly and energy-efficient power devices is expected to trigger a shift in manufacturing of power semiconductors from employing silicon substrates to employing gallium nitride (GaN), silicon carbide (SiC) and gallium nitride on silicon (GaN-on-Si). The new semiconductor substrate technology, which finds application in areas such as electrical power distribution, consumer and automotive electronics in the form of switching devices such as MOSFETs and IGBTs, offers faster switching and high power capabilities and improves efficiency of the power devices. This poses a challenge to power device manufacturers to identify test solutions that facilitate the measurement of high power devices. The APS200TESLA addresses this problem by facilitating high-current and high-voltage device characterization at the wafer level by means of a high-voltage/high-power chuck port, a high-voltage/high-current probe card and the yet to be patented MicroVac high-power chuck capable of handling as low as 50 µm thickness.

The on-wafer testing reduces the time to market and reduces test costs by eliminating the need for dicing and packaging before testing. The device can be interfaced with a host of test instruments via electrical connection. The arc-suppression element allows for flexibility in designing device layout for optimum yield. Safety features such as safety shield to protect operators and damage prevention from high-voltage discharge by auto-discharging and sensing capability through probe pins are incorporated in the device.