A research group of John Fourkas, a Chemistry Professor from the University of Maryland, has created innovative materials and nanofabrication techniques to produce miniaturized components essential for sensors, medical diagnostics and other applications.

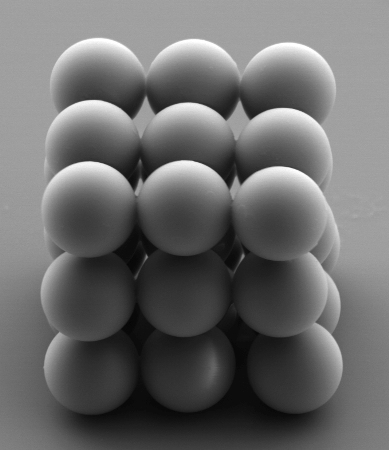

A cube composed of glass microspheres (credit: John Fourkas, University of Maryland)

A cube composed of glass microspheres (credit: John Fourkas, University of Maryland)

It is not possible to create these miniaturized components using traditional techniques. These components may promote rapid analysis using small sample volumes at a lower cost. The research group has synthesized materials that facilitate concurrent three-dimensional (3D) manipulation of tiny objects utilizing optical tweezers and an innovative point-by-point technique for lithography. Using these techniques, the team is able to build intricate 3D structures from numerous miniaturized components.

This work is based on the research group’s previous efforts to utilize visible light to create microscopic structures for building integrated circuits, manipulating behavior of cells and for optical communications. Fourkas informed that the novel materials pave the way to a set of innovative micro and nanofabrication techniques.

The researchers have reported their work in a paper published in Chemical Science. They have also illustrated 3D structures made of glass microspheres, a threaded miniature needle eye, and a tiny tetherball pole in their paper.

This suite of techniques can be used with a variety of materials. For example, it is possible to make functional microfabrics by weaving together threads that have totally different compositions or to perform ‘brick by brick’ fabrication of microscopic devices using building blocks with completely different physical or chemical properties.

Besides allowing technologies to make miniature analytical and diagnostic devices, Fourkas envisages that these techniques hold potential in the analysis and manipulation of the behavior of single and groups of cells.