In a research article that appeared in Optics Express, Drs. Xiaodong Yang and Jie Gao, scientists at Missouri University of Science and Technology, have described a new range of nanoscale slot waveguides that pack 100-1000 folds more transverse optical force when compared to traditional silicon slot waveguides.

Missouri S&T researchers' modeling of stacked nanoscale slot waveguides made of metamaterials shows an optical force 100 to 1,000 times greater than conventional slot waveguides made from silicon.

Missouri S&T researchers' modeling of stacked nanoscale slot waveguides made of metamaterials shows an optical force 100 to 1,000 times greater than conventional slot waveguides made from silicon.

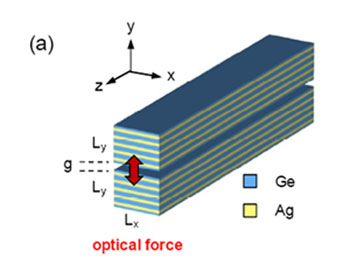

The study results pave the way to develop optical computers, lasers and sensors, informed the researchers. In this work, Yang and Gao formed nano-scale simulations of slot waveguides made of metamaterials comprising alternatively arranged layers of a metal (silver) and a dielectric material (germanium). Waveguides are structures fashioned to channel light beams from one point to other. The researchers replicated what may occur with two simulated identical waveguides stacked with a small air gap between them. They then took measurements of transverse optical force between the waveguides. Optical force is the way of making light beams to repel or attract each other like magnets.

The researchers discovered that the strength of transverse optical forces in hyperbolic metamaterials-made slot waveguides was more than two orders of magnitude of that in traditional dielectric slot waveguides. They mentioned the magnitude as ‘giant’ in their Optics Express article titled ‘Giant transverse optical forces in nanoscale slot waveguides of hyperbolic metamaterials.

The measurement on actual metal-dielectric multilayer structures showed the possibility of experimentally achieving the predicted giant optical forces, explained the researchers. Recently, they also explained about single metamaterial waveguide’s optical properties in a paper entitled ‘Nanoscale metamaterial optical waveguides with ultrahigh refractive indices’ in the Journal of the Optical Society of America. Their next plan is to work on the actual production of metamaterials. Working with Missouri University of Science and Technology’s Materials Research Center, they can employ a focused ion beam scanning electron microscope for modification of materials under analysis. However, they plan to establish a nanofabrication facility at Missouri University of Science and Technology.