Dec 6 2012

Decking your home with holiday lights soon won’t include the hassle of burnt-out bulbs or broken strands.

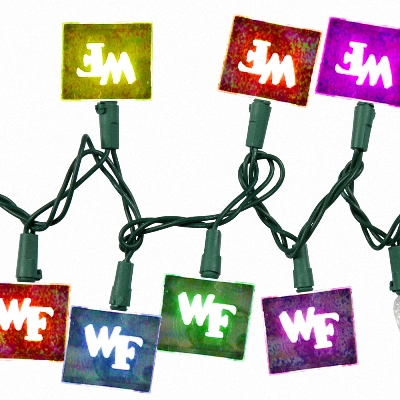

Holiday lights may soon take any shape or color. Rendering uses new FIPEL lighting technology developed by researchers at Wake Forest University.

Holiday lights may soon take any shape or color. Rendering uses new FIPEL lighting technology developed by researchers at Wake Forest University.

Scientists at Wake Forest University have made a new kind of light from moldable plastic, which can glow in any color, won’t shatter – and won’t leave you with the problem of searching for the one bad bulb on a strand of dozens.

“These lights are nearly indestructible and last an incredibly long time,” said David Carroll, Director of the Center for Nanotechnology and Molecular Materials at Wake Forest where the new lighting technology was developed. “I’ve had one going in the lab for 11 years. Plus, you could puncture just one bulb, and the whole strand would still light up your tree.”

Unlike traditional incandescent light bulbs that use filaments and gases to create light, Carroll’s lights are made of three layers of molded plastic that basically glow when turned on.

They aren’t hollow, so they can’t shatter and create a hazard on your floor. They also are at least twice as efficient as the new compact fluorescent bulbs – so your holiday display ends up being a little more affordable and environmentally responsible.

That’s good news, considering that Americans spent about $6 billion last year on Christmas lights and decorations, according to the National Retail Federation.

The technical term for this new product is field-induced polymer electroluminescent device, or FIPEL. Wake Forest has licensed its patents to a company that plans to offer FIPEL lights for commercial use in 2013, with additional uses to follow.