Jan 31 2014

For scientists and engineers, analysing “soft materials” such as plastics, elastomers and composites can be a tricky business.

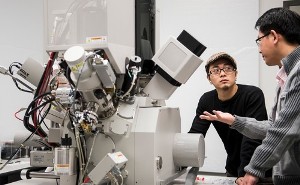

In the Centre for Soft Materials at 4D Labs, graduate student Michael Paul listens to electron microscopist Xin Zhang explain how to operate the FEI Helios Scanning Electron Microscope. Researchers use the tool to perform focused ion-beam milling, cryo-transfer and nanoscale manipulations of samples. They can visualize a sample’s nanoscale features even when they contain water and other soft matter

In the Centre for Soft Materials at 4D Labs, graduate student Michael Paul listens to electron microscopist Xin Zhang explain how to operate the FEI Helios Scanning Electron Microscope. Researchers use the tool to perform focused ion-beam milling, cryo-transfer and nanoscale manipulations of samples. They can visualize a sample’s nanoscale features even when they contain water and other soft matter

Increasingly found in products ranging from contact lenses and biodegradable containers, these soft materials are also used in specialized applications in the medical, clean energy and information sectors—spanning from hydrated membranes in fuel cells to wearable electronic displays and sensors.

But in the laboratory, analysing these soft and easily damaged materials can be fraught with difficulty when using traditional electron microscopy equipment.

New centre has latest technologies

SFU’s 4D LABS, however, has just opened a new Centre for Soft Materials (CSM) that features a suite of the latest technologies for analysing, processing and characterizing soft materials while preserving their nano-scale features.

The $12.4-million centre is the result of a partnership with Western Economic Diversification (WD), the Automotive Fuel Cell Cooperation (AFCC), FEI Company, and Systems for Research (SFR).

High-resolution imaging, 3-D reconstruction, and elemental analysis

Byron Gates, SFU associate professor of chemistry and Canada Research Chair in Surface Chemistry, is excited about the centre’s FEI Helios scanning electron microscope (SEM) system with cryogenic transfer and analysis capabilities.

“Maintaining samples at cryogenic temperatures, a focused ion beam can slice into soft materials while minimizing damage and permitting cross-sectional imaging,” he says.

There’s also an FEI Osiris transmission electron microscope (TEM) that has four integrated energy-dispersive X-ray spectroscopy (EDS) systems for fast compositional analysis. Such analyses were previously unavailable in Western Canada.

“Both of these tools facilitate fast, high-resolution imaging, 3-D reconstruction, and elemental analysis while minimizing damage to soft materials,” says Gates.

The centre includes a full suite of tools for further chemical analysis, characterization and processing of soft materials. These include fuel-cell test stations for evaluating new catalysts and polymer membranes, a system for spray-coating nano-scale and blended materials, and a tabletop SEM with elemental analysis capabilities.

Students gain access to latest tools

“Second-year undergraduates in Earth Science are already using the tabletop SEM as part of their laboratory experience,” says Gates. “We hope that other undergraduate courses will also utilize this equipment, and the other facilities within 4D LABS as well.”

CSM project leads Gates and Mary Boysel, director of operations for 4D LABS, invite faculty and students to visit the new centre to experience hands-on, personalized training on this equipment, as well as on the many other tools and techniques available.