Researchers from North Carolina State University have found a way to reduce the coercivity of nickel ferrite (NFO) thin films by as much as 80 percent by patterning the surface of the material, opening the door to more energy efficient high-frequency electronics, such as sensors, microwave devices and antennas.

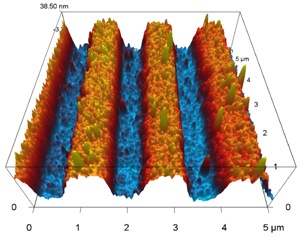

By creating a corduroy pattern on the surface of NFO thin films, researchers have been able to lower the coercivity of the NFO by 30 to 80 percent, depending on the thickness of the film. (Image: Goran Rasic)

By creating a corduroy pattern on the surface of NFO thin films, researchers have been able to lower the coercivity of the NFO by 30 to 80 percent, depending on the thickness of the film. (Image: Goran Rasic)

“This technique reduces coercivity, which will allow devices to operate more efficiently, reducing energy use and improving device performance,” says Goran Rasic, a Ph.D. student at NC State and lead author of a paper describing the work. “We did this work on NFO but, because the reduced coercivity is a direct result of the surface patterning, we think our technique would work for other magnetic materials as well.”

Coercivity is a property of magnetized materials and is the amount of magnetic field needed to bring a material’s magnetization to zero. Basically, it’s how much a material likes being magnetic. For devices that rely on switching current back and forth repeatedly – such as most consumer electronics – you want materials that have low coercivity, which improve device performance and use less energy.

Iron oxides, like NFO, have a variety of properties that are desirable for use in high-frequency devices, but they do have a down side: they have high coercivity. The new research from NC State helps address this problem.

By creating a corduroy pattern on the surface of NFO thin films, researchers have been able to lower the coercivity of the NFO by 30 to 80 percent, depending on the thickness of the film. Thinner films experience a larger reduction in coercivity. The surface pattern on the NFO films consists of raised structures that are 55 nanometers (nm) high and 750 nm wide. The structures run parallel to each other and are spaced 750 nm apart, creating the corduroy effect.

The paper, “Coercivity Reduction in Nickel Ferrite (NiFe2O4) Thin Films through Surface Patterning,” is published online in IEEE Magnetics Letters. Senior author of the paper is Dr. Justin Schwartz, Kobe Steel Distinguished Professor and Department Head of the Materials Science and Engineering Department at NC State.