May 16 2014

Xanofi, a nanomaterial company specializing in rapid product development, announces the global release of XanoMatrix™, a suite of next generation 3D cell culturing products. The products will be shown at BIOtech 2014 in Tokyo, May 14-16 as well as the BIO International Convention on June 23-26.

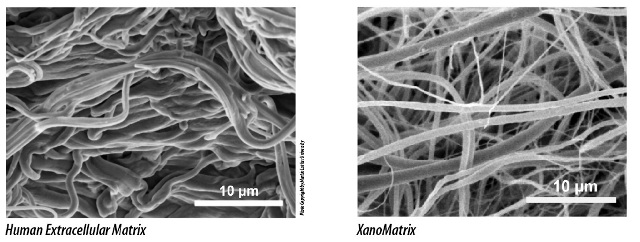

XanoMatrix scaffolds solve many of the critical issues facing advance 3D cell culturing by using the advantages of nano-sized fibers to create a highly porous structure that cells can penetrate and remodel. Working with researchers some of the world’s best medical institutions (the University of North Carolina, University College London and the University of Cambridge), Xanofi’s unique 3D structures have been demonstrated as an excellent environment for the growth of stem cells, various cancer cells, and different primary cells. XanoMatrix can be used in a wide range of cell growth applications, from fixed bed reactors, regenerative medicine applications, laboratory plate culturing, in vitro cancer work, etc. The material can even be sprayed through 3D printers or shaped into almost any form.

By using Xanofi’s discrete length nanofiber products, the fibrous structure is evenly spread throughout the z-axis of the entire scaffold. Additionally, routine assays such as fluorescent microscopy, cell viability/proliferation, RNA/DNA analysis, cryosectioning, and protein extraction are all possible with little-to-no change in current protocols. Ease of use of the scaffolds allows complex co-culturing or even complete multiple cell type tissue modeling.

"The key to XanoMatrix is the use of short, staple nanofibers that allow cells to remodel the scaffold while establishing dynamic nutrient gradients,” said Miles Wright, CEO of Xanofi. “It’s probably the closest biomimic to ECM on the market and can be customized to provide solutions in several key areas of tissue engineering.”

About Xanofi

Xanofi, a highly innovative advanced materials company, is changing the global landscape on how nanofibers are manufactured with a new platform process that is highly efficient and easy to integrate into production environments. Using a patented technique called XanoShear™, the scalable Xanofi process can produce short, staple nanofibers at high yields. The ability to control the length of nanofibers allows this technology to find application in a wide swath of both conventional and unconventional applications. See more detailed information by visiting www.xanofi.com.