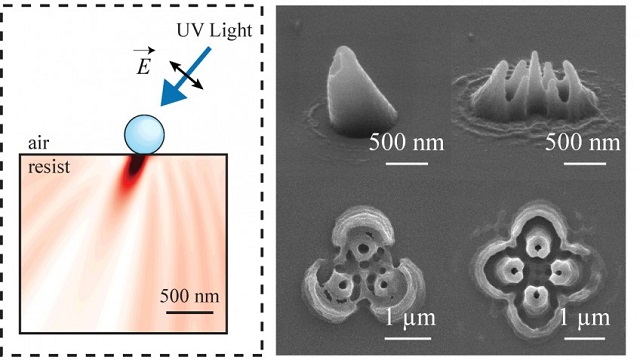

A variety of asymmetric hollow-core three-dimensional nanostructures fabricated by illuminating light on nanoparticles. Image credit: Xu Zhang.

A variety of asymmetric hollow-core three-dimensional nanostructures fabricated by illuminating light on nanoparticles. Image credit: Xu Zhang.

A new nanolithography technique that uses nanoscale polystyrene spheres to create 3D nanostructures for biomedical, photonic and electronic applications has been developed by researchers at the North Carolina State University (NC State).

Usually, conventional techniques involve stacking of 2D patterns for creating 3D structures and they are comparatively more expensive than the new nanolithography technique.

Our approach reduces the cost of nanolithography to the point where it could be done in your garage.

Senior author of the paper on this study and an assistant professor of mechanical and aerospace engineering at NC State, Dr. Chih-Hao Chang

In order to create 2D patterns, light has to be focused on photosensitive films. Different types of techniques have been used in traditional lithography methods. However, they depend on very expensive lasers, electron beams, specialized lenses or mechanical probes. Using these techniques, 3D structures can be created by printing 2D patterns layer after layer, over each other.

The novel technique developed at NC State involves placing of nanoscale polystyrene spheres over a photosensitive film’s surface. These nanospheres are transparent. When light hits the nanosphere, the light takes a specific angle, and bends and scatters. This happens in a predictable manner. Nanolithography can be controlled by altering the exposure duration, polarization, wavelength and angle of light, and the nanosphere’s size. Furthermore, single or multiple beams of light can be used for creating different types of nanostructure designs.

We are using the nanosphere to shape the pattern of light, which gives us the ability to shape the resulting nanostructure in three dimensions without using the expensive equipment required by conventional techniques, and it allows us to create 3D structures all at once, without having to make layer after layer of 2D patterns.

Dr. Chang

NC State researchers have demonstrated that nanospheres could be made to self-assemble in an array that is regularly-spaced, and this could be used for producing 3D nanostructures with a uniform pattern.

The lead author of the paper and a Ph.D. student in Dr. Chang’s lab, Xu Zhang, states that “This could be used to create an array of nanoneedles for use in drug delivery or other applications.”

The novel technique can be used for creating nanoscale “inkjet printers” which can be used for creating photonic components and antennas, and for printing biological cells and electronics.

Xu Zhang commented that “For this work, we focused on creating nanostructures using photosensitive polymers, which are commonly used in lithography, but the technique could also be used to create templates for 3D structures using other materials.”

NC State researchers are presently working on new methods to manipulate the method for controlling the shape of the final structures.

We’re exploring the use of nanosphere materials other than polystyrene, as well as nanoparticle shapes other than spheres, and ultimately we want to look at ways of controlling the placement of particles on the photosensitive film in patterns other than uniform arrays.

Dr. Chang

The researchers have published their study online as “Sculpting Asymmetric Hollow-Core Three-Dimensional Nanostructures Using Colloidal Particles,” in the journal Small. Undergraduates Zhiyuan Xu and Bin Dai, had co-authored this paper. These undergraduates had worked on this project as part of NC State’s Global Training Initiative program with Jiangsu University.

The NASA Early Career Faculty grant number NNX12AQ46G had provided support for this study. NC State’s Nanosystems Engineering Research Center for Advanced Self-Powered Systems of Integrated Sensors and Technologies had also provided support under grant number EEC-1160483.

References