A research group has taken kirigami to the nanoscale by using graphene, single atom-thick sheets of hexagonally bonded carbon, as their template.

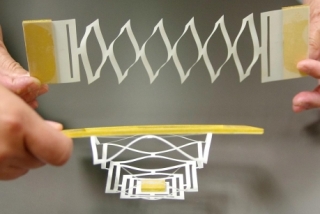

Graphene, like the paper models, is strong but flexible, and can be stretched or pulled with forces comparable to those exerted by motor proteins. (Credit: Joe Wilensky/Cornell Chronicle)

Graphene, like the paper models, is strong but flexible, and can be stretched or pulled with forces comparable to those exerted by motor proteins. (Credit: Joe Wilensky/Cornell Chronicle)

The kirigami art involves producing complex designs through paper cuttings. The researchers, led by Paul McEuen, the John A. Newman Professor of Physical Science and director of the Kavli Institute for Nanoscale Science (KIC) at Cornell, applied kirigami techniques to 10µm graphene sheets.

By cutting, folding and twisting graphene, and ultra-strong, highly conductive material, this technique could allow the smallest machines in the world to be created.

The research was published in the July 29 edition of the journal Nature.

As graphene and other thin materials tend to be sticky at the nanoscale, the researchers employed an old technique to manipulate it. This technique involves suspending graphene in water, followed by adding surfactants to make it greasy, like soapy water. The researchers also formed “handles” from gold at each end of the graphene strands. The manipulation of graphene in this manner was figured out by co-author Arthur Barnard, a Cornell physics graduate student.

The lead author of the study, Melina Blees, a former physics graduate student and now a postdoctoral researcher at the University of Chicago, worked out the initial designs using paper and fabric, in the library of the University of Chicago's Department of Art, where they received an "enthusastic welcome".

After making paper models of their designs, the researchers then worked on translating the techniques to graphene, at the Cornell Nanoscale Science and Technology Facility.

It was really true exploration, cutting things out of paper and playing with them, trying to imagine how a 'hanging kirigami mobile for kids' could become a nanoscale spring for measuring forces or interacting with cells.

Melina Blees, lead author

Graphene kirigami behaves like a soft spring. Credit: McEuen lab

A computer-controlled needle pushes on a graphene sheet. The graphene crumples and deforms like a sheet of tissue paper, and recovers its original shape. Credit: McEuen lab

The researchers tested their graphene kirigami designs on laser-cut paper. They found that a graphene soft spring behaved similarly to the paper model. Credit: McEuen lab

One of the structures the researchers fabricated was a soft spring, that acted like a flexible transistor, using one graphene sheet. McEuen said that the forces required to bend the spring are similar to the forces exerted on a motor protein. These experiments could lead to new ideas, such as flexible, nanoscale devices that could be introduced into human cells, or into the brain for sensing.

The researchers also demonstrated the way in which graphene can bend in a simple hinge design, and measured the forces involved. They observed a perfectly intact and elastic design after opening and closing the hinge 10,000 times, indicating the structure would be robust enough for foldable machines and devices at that scale.

Based on these principles, another research team at Cornell has received funding from the Department of Defense to continue research on the technologies related to flexible materials like graphene, with the help of the demonstrated kirigami principles.

Blees commented on the experience of working directly with graphene, an unusual experience even for nanotechnology researchers:

It's one thing to read about how strong graphene is; it's another thing entirely to crumple it up and watch it recover, or to stretch a spring dramatically without tearing the materials.

It's not every day that you get to develop a feel for a nanoscale material, the way an artist would.

The work, which also involved David Muller, professor of applied and engineering physics and co-director of KIC, was supported by the Cornell Center for Materials Research, which is FUNDED by the National Science Foundation; the Office of Naval Research; and the Kavli Institute at Cornell for Nanoscale Science.

References and further reading