Researchers at the University of Twente's MESA+ research institute have revealed that excellent quality magnetic thin films can be produced using 2D crystals, also known as nanosheets, allowing the preferred direction of the magnetism to be controlled locally.

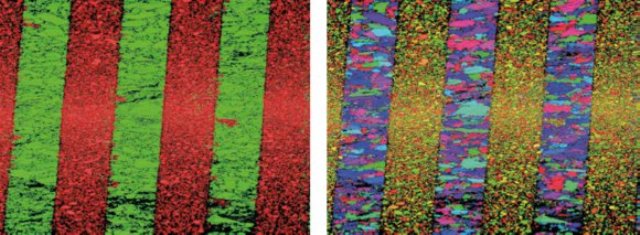

EBSD image showing the local structure of a thin film. The left half of these images shows the preferred direction of the LaSrMnO3-film perpendicular to the growth direction, while the right half shows the directions in the plane with the contours of the individual nanosheets clearly visible. The distance between two lines in the pattern is a few micrometers.

EBSD image showing the local structure of a thin film. The left half of these images shows the preferred direction of the LaSrMnO3-film perpendicular to the growth direction, while the right half shows the directions in the plane with the contours of the individual nanosheets clearly visible. The distance between two lines in the pattern is a few micrometers.

The team's paper, published in Advanced Functional Materials, describes the technique to fabricate micrometer-scale magnetic patterns. In another paper published in Angewandte Chemie, the researchers illustrate a method for producing the nanosheets in seconds, a production process that usually takes longer. These magnetic films are in demand for a variety of applications, including advanced smartphones.

Controlled growth of thin layers of specific materials can be accomplished using pulsed laser deposition (PLD). In this method, a powerful laser beam heats a material rapidly, causing the material to evaporate, and producing a plasma. This is then distributed rapidly in a vacuum chamber, and gets deposited on a substrate to form a thin layer. Thus, the thickness of the layer can be controlled.

This method allows the thickness of the layers to be controlled so that smooth and thin layers can be formed. These often have special properties which make them suitable for application in electronics, electro-mechanics, and other fields.

It is important to form patterns in the newly created layered materials, especially for these applications. This step is quite a challenge as the substrate has to be heated above 500°C over the course of the PLD process. The methods that are currently used are no compatible with the manufacturing techniques currently applied for microstructures.

Use of Nanosheets

The UT team has formulated a method wherein nanosheets created from 3D crystals with a layered structure are used. When the crystals are dissolved in a particular liquid, they spontaneously disintegrate to form single nanosheets. Previously, scientists believed that the disintegration process could take more than a week. However, the UT researchers have proved that the nanosheets can be formed in seconds, therefore making it possible to manufacture nanosheets on a much larger scale.

With this method in place, different types of nanosheets can be introduced in micro-patterns on a substrate. Applying the PLD method, these micro-patterns form the base for developing thin magnetic layers of magnetic LaSrMnO3 at elevated temperatures.

The structure of the magnetic film is based on the type of nanosheet, and therefore forms a specific orientation accordingly. The magnetism of the film is established at that location.

Different methods, such as electron backscatter diffraction (EBSD), can be used to observe the process. EBSD exposes the structure in the patterns.

Functional Properties

The UT team has clearly demonstrated ways to use the micro patterns to control a material’s useful properties. Besides magnetism, patterning of other properties can also be performed at the micrometer scale. This breakthrough is helpful in bridging the gap between research into artificial layered crystals and their final applications. The Twente group is a pioneer in this field.

Research

The team was made up of researchers from the Inorganic Materials Science department of UT research institute MESA+. This research is a part of the TOP project funded by the Netherlands Organisation for Scientific Research (NWO) and the Chinese Scholarship Council. The Condensed-Matter and Medical Physics group at the University of California (UC, Irvine) also contributed to the study.