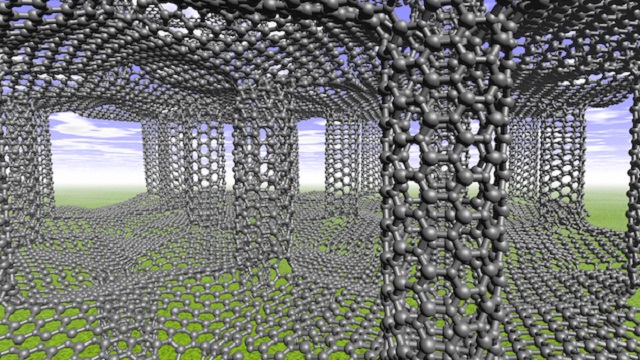

Carbon nanotube pillars between sheets of graphene may create hybrid structures with a unique balance of strength, toughness and ductility throughout all three dimensions, according to Rice University scientists. Five, seven or eight-atom rings at the junctions can force the graphene to wrinkle. Illustration by Shuo Zhao and Lei Tao

Carbon nanotube pillars between sheets of graphene may create hybrid structures with a unique balance of strength, toughness and ductility throughout all three dimensions, according to Rice University scientists. Five, seven or eight-atom rings at the junctions can force the graphene to wrinkle. Illustration by Shuo Zhao and Lei Tao

Researchers from Rice University have found that the introduction of nanotube pillars between graphene sheets produces hybrid structures that exhibit a distinctive balance of toughness, strength and ductility in all the three dimensions.

Carbon nanomaterials are being used in the form of nanotubes, flat sheets and spheres. They are also considered as potential building blocks in developing hybrid structures with distinct properties for heat transport, strength and electronics. The researchers are establishing a theoretical base for such hybrid structures by focusing on the effect of the junctions of blocks on the properties of the desired materials.

The team consists of materials scientist - Rouzbeh Shahsavari and alumnus Navid Sakhavand. They determined how different links, especially the links between graphene and carbon nanotubes, influence the properties of the final hybrid in all three directions. They discovered that by introducing junctions, the flexibility is increased while maintaining the same strength as that of materials composed of layered graphene. Their findings were published in the journal- Carbon.

Carbon nanotubes are nanomaterials with rolled-up arrays of atoms arranged as perfect hexagons, while graphene is a rolled-out sheet of carbon atoms. Both these materials exhibit excellent strength and heat and electron transmitting capabilities. These properties are affected when these two materials are joined together, depending on the arrangement of atoms.

Some labs are actively trying to make these materials or measure properties like the strength of single nanotubes and graphene sheets. But we want to see what happens and quantitatively predict the properties of hybrid versions of graphene and nanotubes. These hybrid structures impart new properties and functionality that are absent in their parent structures — graphene and nanotubes.

Shahsavari

For that reason, 3D computer models of “pillared graphene nanostructures” were assembled in the lab, similar to the way boron-nitride structures was arranged in a previous study for analyzing the heat transfer between layers.

This time we were interested in a comprehensive understanding of the elastic and inelastic properties of 3-D carbon materials to test their mechanical strength and deformation mechanisms. We compared our 3-D hybrid structures with the properties of 2-D stacked graphene sheets and 1-D carbon nanotubes.

Shahsavari

Layered sheets of graphene retain their properties in-plane, however, show thermal conductance or stiffness between sheets. The pillared graphene model exhibited much more strength and stiffness, and a 42% increase in out-of-plane ductility, which is the ability to deform without breaking when subjected to stress. He added that pillared graphene showed high toughness along the out-of-plane directions, which was not found in 2D stacked graphene sheets or 1D carbon nanotubes.

The researchers measured how the innate energies from atoms force hexagons to either add on or lose atoms to neighbouring rings, which depended on how they merge with the neighbouring atoms. They were able to determine a measure of control over the mechanical properties of the hybrid when they forced five, seven or up to eight atom rings. Shahsavari explained that formation of wrinkles in the sheets of graphene by tuning the nanotubes in a specific fashion extended the shear compliance and flexibility.

During the eventual fracture of the material, it was observed that the likelihood of fracture was more at the eight-member rings due to the accumulation of strain induced by the stress. This observation led to the conclusion that such hybrids could be tuned to fail under specific conditions.

This is the first time anyone has created such a comprehensive atomistic ‘lens’ to look at the junction-mediated properties of 3-D carbon nanomaterials. We believe the principles can be applied to other low-dimensional materials such as boron nitride and molybdenum/tungsten or the combinations thereof.

Shahsavari

References